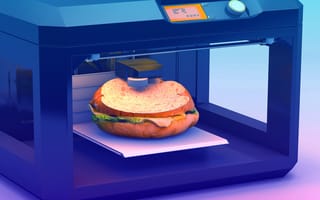

3D-printed food consists of eatables prepared via the automated, additive process of 3D printing. Similar to other methods of printing, 3D-printed food is constructed in intricate shapes, layer by layer. In this version, however, the filament is swapped out for an edible resin.

“Much like how Lego blocks can be used to build structures of nearly any shape, 3D printing foods allows manufacturers to have greater control over the final shape, nutrition and taste characteristics of the product,” food scientist Bryan Quoc Le told Built In.

What Is 3D-Printed Food?

3D-printed food is created from a semi-automated, additive manufacturing process that layers edible filament to create various eatables.

These printers recreate an uploaded artwork, original or pre-fixed, from a digital file using computer-aided design (CAD) software. And, instead of plastics, they dispense paste-like or malleable foodstuffs, spanning pasta, chocolate, cheese, cookie dough, sugar-based confectionery, gelatin, cultured meat, mashed potatoes and pizza.

The main attraction of 3D-printed cuisine — its customizability — lures big players into this space. This list includes tech-health startups researching ways to treat dysphagia, a condition in which patients experience difficulty when swallowing, and NASA, which is in search of nutrient-rich meals for astronauts in space. An assortment of sustainable food companies are joining the ranks, developing semi-automated means of mass food production in an effort to disrupt conventional farming methods.

How Does 3D-Printing Food Work?

Printing food in 3D emulates a pastry chef piping icing on a cake. As the arm moves along the spongy perimeter, a colorful whipped sugar takes the shape of a handler’s design.

“Typically the food is in a paste or mush format that’s inserted into a canister to put into the printer,” said Justin Haines, the founder and CEO of Haines Additive Manufacturing, which features a line of 3D-food printers.

While the operator uploads a design, the food is heated inside of the machine. This step isn’t for cooking the food product, but rather to thermally increase its malleability in preparation to print.

Layer by layer, an edible resin is pushed through a syringe-like dispenser, called an extruder, and deposited onto a build plate at specific points along a three-axis system. As the computerized robot moves along its aluminum frame, it prints a filament made up of curated powdered or liquefied ingredients per a preprogrammed recipe.

“When the food is dispensed from the nozzle, it falls onto a cold print bed,” Haines said. “It quickly congeals before the nozzle comes back around to print layers for added strength.”

Throughout the printing process, the perishables undergo an instantaneous curing process. Materials rapidly heat, cool and then set in a series of chemical reactions, ultimately fixing the ingredients into place, explained Le, who is also author of 150 Food Science Questions Answered.

“Sometimes the ingredient itself already has enough viscosity and solidity to remain static, such as doughs or gels,” Le said.

What Does 3D-Printed Food Taste Like?

As it turns out, the taste of a 3D-printed edible should be what you’d expect, depending on what food type or flavor is loaded into a 3D-printer filament.

Essentially, what goes in comes right back out. The amount of heat exposure an ingredient undergoes during the printing process has no significant effect.

“So you won’t detect any difference in taste,” explained Tom Jacobs, a 3D-food printing expert at food tech company byFlow who spent nearly a decade working as a professional chef in Michelin Star restaurants.

What a printer can do, however, is influence the sensorial properties of a product by printing it in a textural pattern, known as an infill, Jacobs said. Pralines, for example, exhibit different melting behaviors when constructed as hollow or when the chocolate resin is manipulated in a way that alternates textural layers from hard to soft.

“But, apart from the texture, the taste itself is unchanged,” he added.

Is 3D-Printed Food Safe?

Yes, 3D-printed food is safe if printed in a clean environment. Regular food-handling and health codes should be adhered to, including sanitized equipment and fresh ingredients.

Pros of 3D-Printed Food

Customizable and Semi-Automated

The indisputable advantage of 3D-printed foods is in the medium’s customizability. An operator can control the shape, structure, flavor profile and nutritional stability of a dish by integrating different ingredients into the 3D-printing process. Plus, dispensing 3D-printed food material is semi-automated thanks to machinery, so food structures don’t have to be layered by hand.

“Personalization can be done at different levels, from printing your name or photo in chocolate to manipulating a product at the nutrient level so it fits your body’s needs,” Jacobs said.

Can Be Made to Target Nutritional Needs

Three-dimensionally printed food can also be manipulated in a way to target a diner’s nutritional needs. Tokyo-based restaurant Sushi Singularity, for example, crafts custom rolls based on a customer’s submitted health test kit. Biometrics are collected from vials of their saliva, urine and stool samples upon booking a reservation.

And Biozoon and Natural Machines are adapting 3D-food printing tech to help feed older adults. More specifically, these innovation hubs are leveraging molecular gastronomy to make mushier meals, aiding those who have dysphagia or difficulty swallowing.

Low Waste and Low Storage Food Option

NASA teamed with a Silicon Valley startup named Beehex with the idea that 3D-printed pizza may be the key to feeding astronauts on long haul, aerospace trips. Keeping ingredients — in the form of paste-loaded cartridges — as fresh as possible over a long period of time, such as five-year endeavors to Mars, and with little to no waste or storage space is crucial to the success of a space mission.

Can Be Used as a Marketing Tool

Oreo took full advantage of 3D-printed food’s customizability at its SXSW booth in 2014 when they wowed festival-goers with tailor-made sandwich biscuits, 3D-printing cream filling in the color of their choice on-demand. As part of a marketing campaign, mayonnaise manufacturer Hellmann’s 3D-printed customer caricatures using its signature sauce onto burger patties from a food truck.

Suitable for Mass Production

Another advantage to 3D printing is its ability to be scaled in a way to guarantee uniformity across mass food production. So while these proof of concepts are primed for the mass market, companies will be able to customize culinary creations at volume.

Cons of 3D-Printed Food

Limited Available Ingredients

Due to 3D-printed food’s niche market and lack of wide-spread use, ingredients made specifically for these foods are scarce, and there are not many manufacturers of food-ink ingredients. “At this time, there is a limited number of ingredients that are suitable for the 3D-printing process,” Le said.

Expensive Equipment

The process of 3D printing food is relatively expensive compared to established methods of food making, especially for complex recipes. Just purchasing a 3D-food printer would set someone back by $1,000 to $5,000, which is the average price range, according to additive manufacturing marketplace Aniwaa.

Not Built for Home Use

Some 3D printers and other technologies used in the 3D-printed food process can be large in size and require trained staff to operate them. This is particularly the case for 3D-printed meats, which can require incubation and specific climate-controlled environments during creation. These aspects make 3D food printers widely inaccessible — and sometimes impossible — for consumers to use in their own homes.

“For the time being, 3D-food printing is more suitable for mass-scale commercial production rather than individual household use due to its relative complexity,” Le said.

Texture, Taste and Nutrients May Not Match Traditional Food

Though 3D-printed food aims to mimic the taste, feel and nutritional value of their traditional counterparts, it’s not guaranteed to be exact. This is especially the case for 3D-printed meats, which can use cultivated cells or plant-based proteins in lieu of direct meat cuts.

Examples of 3D-Printed Food

Chocolate

United Kingdom-based manufacturer Choc Edge — the widely recognized originators of commercial-grade, 3D-printed chocolate — has released two versions of its 3D-food printers that dispenses machine-tempered chocolate resin to create elaborate, edible designs.

For ready-made collections, artisanal chocolatier Ryan L Foote plays with hard angular lines as well as bulbous shapes across his designer chocolate collections. Through its Mona Lisa 3D Studio, chocolate manufacturer Barry Callebaut creates custom orders of crystalized chocolate with “innovative shapes and designs that were impossible to be produced before” using conventional methods.

Fish

No fishing required, faux-seafood startup Oshi is producing vegan boneless, whole-cut salmon filets with comparative nutritional benefits to the real thing. Sharing this space is seafood-alternative startup Revo Foods, which is making smoked salmon, salmon spread, gravlax and tuna spread from ingredients such as pea proteins, algae and plant oils, to name a few.

Mashed Potatoes

Out of all of these categories, mashed potatoes may yield the most ideal texture for 3D-printing projects. But aside from crafting opulent patterns, there is an increased interest in using potatoes as a carrier food to be supplemented with nutritional additives.

In one successful study, researchers injected probiotics to a mashed potato mix in an effort to enhance its nutritional value, artificially creating a functional food. The experiment also aimed to optimize the potato filament’s formulation for 3D printing.

In another study, researchers at Texas Tech University and The Ohio State University used proteins and lipid powders as additives to improve the printability and nutrition of 3D-printed mashed potatoes.

Meat

Steakholder Foods is recreating steak using a bio “ink” scaffolded from stem cell lines. This ink is then loaded into a machine that bioprints a meat cut from a digital design before being placed in an incubator, where cells will differentiate into muscle and fat cells for weeks.

Researchers at Osaka University in Japan are on a similar path in their replication of Wagyu beef, a meat cut prized for its intramuscular structure and distinctive texture.

For poultry, GOOD Meat produces cell-cultivated, 3D-printed chicken for sale in the United States and Singapore.

Biotech company Modern Meadow specializes in protein applications, producing steak chips and genuine, lab-grown leather from its 10,000-square-foot biofabrication facility in Brooklyn, New York. Compared to conventional farming methods, they estimate their means of production at just one percent of land use, four percent of water use and 55 percent of energy use, with no slaughter necessary.

Meat Substitutes

Food tech company Redefine Meat uses 3D printing to duplicate the exact muscle and fat structures found in cuts of marbled meat, reproducing the mouthfeel of a teeth-sinking, carnivorous experience. Its plant-based menu includes faux-beef tenderloin, lamb flanks and bratwurst across a multi-item product line.

Similarly, Barcelona-based Novameat is 3D printing plant-based chicken, beef and turkey cuts, utilizing pea protein and fava bean protein concentrate to provide a meat-like substitute.

And Hong Kong-based Alt Farm is tackling plant-based ribeye, striploin, tenderloin and Wagyu beef substitutes made from pea, soy and algae.

Pasta

Household pasta brand Barilla launched a spinoff project in BluRhapsody, which offers a service that provides chefs with their own customized 3D-printed pasta shapes. Mixing durum wheat semolina with water, natural extracts and coloring properties, the resin takes on many shapes — like hearts, stars, pottery-esque kalpis and even sea urchins.

Pizza

Since working with NASA, Beehex has pivoted its pizza product to the commercial market. With an assist from the company’s robot, Chef 3D, a 12-inch pie can be ready to serve in about six minutes. First, it lays down the dough — which can take the shape of any uploaded jpeg file, and comes in plain, tomato and gluten-free varieties, then a sauce and cheese of choice.

Sugar

In operation since 2012, the Sugar Lab’s digital bakery prints out themed collections of sweets, from Star Wars and floral skull drink drops to sushi roll bonbons, using a mix of powdered sugar and water. Meanwhile, at the CandyFab Project, researchers are able to construct large-set, sugary sculptures by melting granulated sugar together with hot air.

Frequently Asked Questions

Is it possible to 3D print food?

Yes. 3D printing can be used to create foods like meat, fish, pasta, pizza, chocolate and more.

What is 3D-printed food made out of?

3D-printed food is made out of edible resin or filament, which is dispensed in layers to create the food's shape and structure. The ingredients making up the edible material will vary depending on the food that is being made.

Is 3D-printed food safe?

Yes. 3D-printed food is safe to eat as long as it is printed in a clean environment, prepared with fresh ingredients and cooked properly.

What are the disadvantages of 3D-printed food?

Disadvantages of 3D-printed food can include:

- Limited availability of ingredients

- Expensive equipment

- Unsuitability for use at home

- Lack of texture, taste or nutritional similarities in comparison to traditionally made foods