Robotics is an interdisciplinary sector of science and engineering dedicated to the design, construction and use of mechanical robots. Our guide will give you a concrete grasp of robotics, including different types of robots and how they’re being applied across industries.

What Is Robotics?

Robotics is the intersection of science, engineering and technology that produces machines, called robots, that replicate or substitute for human actions. Robots perform basic and repetitive tasks with greater efficiency and accuracy than humans, making them ideal for industries like manufacturing. However, the introduction of artificial intelligence in robotics has given robots the ability to handle increasingly complex situations in various industries.

What Is a Robot?

A robot is a programmable machine that can complete a task, while the term robotics describes the field of study focused on developing robots and automation. Each robot has a different level of autonomy. These levels range from human-controlled bots that carry out tasks to fully-autonomous bots that perform tasks without any external influences.

In terms of etymology, the word ‘robot’ is derived from the Czech word robota, which means “forced labor.” The word first appeared in the 1920 play R.U.R., in reference to the play’s characters who were mass-produced workers incapable of creative thinking.

Robotics Aspects

Mechanical Construction

The mechanical aspect of a robot helps it complete tasks in the environment for which it’s designed. For example, the Mars 2020 Rover’s wheels are individually motorized and made of titanium tubing that help it firmly grip the harsh terrain of the red planet.

Electrical Components

Robots need electrical components that control and power the machinery. Essentially, an electric current — a battery, for example — is needed to power a large majority of robots.

Software Program

Robots contain at least some level of computer programming. Without a set of code telling it what to do, a robot would just be another piece of simple machinery. Inserting a program into a robot gives it the ability to know when and how to carry out a task.

What Are the Main Components of a Robot?

Control System

Computation includes all of the components that make up a robot’s central processing unit, often referred to as its control system. Control systems are programmed to tell a robot how to utilize its specific components, similar in some ways to how the human brain sends signals throughout the body, in order to complete a specific task. These robotic tasks could comprise anything from minimally invasive surgery to assembly line packing.

Sensors

Sensors provide a robot with stimuli in the form of electrical signals that are processed by the controller and allow the robot to interact with the outside world. Common sensors found within robots include video cameras that function as eyes, photoresistors that react to light and microphones that operate like ears. These sensors allow the robot to capture its surroundings and process the most logical conclusion based on the current moment and allows the controller to relay commands to the additional components.

Actuators

A device can only be considered to be a robot if it has a movable frame or body. Actuators are the components that are responsible for this movement. These components are made up of motors that receive signals from the control system and move in tandem to carry out the movement necessary to complete the assigned task. Actuators can be made of a variety of materials, such as metal or elastic, and are commonly operated by use of compressed air (pneumatic actuators) or oil (hydraulic actuators) but come in a variety of formats to best fulfill their specialized roles.

Power Supply

Like the human body requires food in order to function, robots require power. Stationary robots, such as those found in a factory, may run on AC power through a wall outlet but more commonly, robots operate via an internal battery. Most robots utilize lead-acid batteries for their safe qualities and long shelf life while others may utilize the more compact but also more expensive silver-cadmium variety. Safety, weight, replaceability and lifecycle are all important factors to consider when designing a robot’s power supply.

Some potential power sources for future robotic development also include pneumatic power from compressed gasses, solar power, hydraulic power, flywheel energy storage organic garbage through anaerobic digestion and nuclear power.

End Effectors

End effectors are the physical, typically external components that allow robots to finish carrying out their tasks. Robots in factories often have interchangeable tools like paint sprayers and drills, surgical robots may be equipped with scalpels and other kinds of robots can be built with gripping claws or even hands for tasks like deliveries, packing, bomb diffusion and much more.

How Do Robots Work?

Some robots are pre-programmed to perform specific functions, meaning they operate in a controlled environment where they do simple, monotonous tasks — like a mechanical arm on an automotive assembly line.

Other robots are autonomous, operating independently of human operators to carry out tasks in open environments. In order to work, they use sensors to perceive the world around them, and then employ decision-making structures (usually a computer) to take the optimal next step based on their data and mission.

Robots may also work by using wireless networks to enable human control from a safe distance. These teleoperated robots usually work in extreme geographical conditions, weather and circumstances. Examples of teleoperated robots are the human-controlled submarines used to fix underwater pipe leaks during the BP oil spill or drones used to detect landmines on a battlefield.

Types of Robotics

Humanoid Robots

Humanoid robots are robots that look like or mimic human behavior. These robots usually perform human-like activities (like running, jumping and carrying objects), and are sometimes designed to look like us, even having human faces and expressions. Two of the most prominent examples of humanoid robots are Hanson Robotics’ Sophia and Boston Dynamics’ Atlas.

Cobots

Cobots, or collaborative robots, are robots designed to work alongside humans. These robots prioritize safety by using sensors to remain aware of their surroundings, executing slow movements and ceasing actions when their movements are obstructed. Cobots typically perform simple tasks, freeing up humans to address more complex work.

Industrial Robots

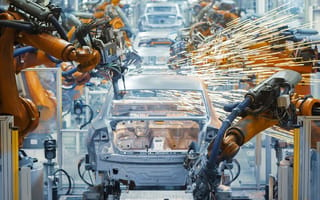

Industrial robots automate processes in manufacturing environments like factories and warehouses. Possessing at least one robotic arm, these robots are made to handle heavy objects while moving with speed and precision. As a result, industrial robots often work in assembly lines to boost productivity.

Medical Robots

Medical robots assist healthcare professionals in various scenarios and support the physical and mental health of humans. These robots rely on AI and sensors to navigate healthcare facilities, interact with humans and execute precise movements. Some medical robots can even converse with humans, encouraging people’s social and emotional growth.

Agricultural Robots

Agricultural robots handle repetitive and labor-intensive tasks, allowing farmers to use their time and energy more efficiently. These robots also operate in greenhouses, where they monitor crops and help with harvests. Agricultural robots come in many forms, ranging from autonomous tractors to drones that collect data for farmers to analyze.

Microrobotics

Microrobotics is the study and development of robots on a miniature scale. Often no bigger than a millimeter, microrobots can vary in size, depending on the situation. Biotech researchers typically use microrobotics to monitor and treat diseases, with the goal of improving diagnostic tools and creating more targeted solutions.

Augmenting Robots

Augmenting robots, also known as VR robots, either enhance current human capabilities or replace the capabilities a human may have lost. The field of robotics for human augmentation is a field where science fiction could become reality very soon, with bots that have the ability to redefine the definition of humanity by making humans faster and stronger. Some examples of current augmenting robots are robotic prosthetic limbs or exoskeletons used to lift hefty weights.

Software Bots

Software bots, or simply ‘bots,’ are computer programs which carry out tasks autonomously. They are not technically considered robots. One common use case of software robots is a chatbot, which is a computer program that simulates conversation both online and over the phone and is often used in customer service scenarios. Chatbots can either be simple services that answer questions with an automated response or more complex digital assistants that learn from user information.

Robotics Applications

Beginning as a major boon for manufacturers, robotics has become a mainstay technology for a growing number of industries.

Manufacturing

Industrial robots can assemble products, sort items, perform welds and paint objects. They may even be used to fix and maintain other machines in a factory or warehouse.

Healthcare

Medical robots transport medical supplies, perform surgical procedures and offer emotional support to those going through rehabilitation.

Companionship

Social robots can support children with learning disabilities and act as a therapeutic tool for people with dementia. They also have business applications like providing in-person customer service in hotels and moving products around warehouses.

Home Use

Consumers may be most familiar with the Roomba and other robot vacuum cleaners. However, other home robots include lawn-mowing robots and personal robot assistants that can play music, engage with children and help with household chores.

Search and Rescue

Search and rescue robots can save those stuck in flood waters, deliver supplies to those stranded in remote areas and put out fires when conditions become too extreme for firefighters.

Pros and Cons of Robotics

Robotics comes with a number of benefits and drawbacks.

Pros of Robotics

- Increased accuracy. Robots can perform movements and actions with greater precision and accuracy than humans.

- Enhanced productivity. Robots can work at a faster pace than humans and don’t get tired, leading to more consistent and higher-volume production.

- Improved safety. Robots can take on tasks and operate in environments unsafe for humans, protecting workers from injuries.

- Rapid innovation. Many robots are equipped with sensors and cameras that collect data, so teams can quickly refine processes.

- Greater cost-efficiency. Gains in productivity may make robots a more cost-efficient option for businesses compared to hiring more human workers.

Cons of Robotics

- Job losses. Robotic process automation may put human employees out of work, especially those who don’t have the skills to adapt to a changing workplace.

- Limited creativity. Robots may not react well to unexpected situations since they don’t have the same problem-solving skills as humans.

- Data security risks. Robots can be hit with cyber attacks, potentially exposing large amounts of data if they’re connected to the Internet of Things.

- Maintenance costs. Robots can be expensive to repair and maintain, and faulty equipment can lead to disruptions in production and revenue losses.

- Environmental waste. Extracting raw materials to build robots and having to discard disposable parts can lead to more environmental waste and pollution.

Future of Robotics

The evolution of AI has major implications for the future of robotics. In factories, AI can be combined with robotics to produce digital twins and design simulations to help companies improve their workflows. Advanced AI also gives robots increased autonomy. For example, drones could deliver packages to customers without any human intervention. In addition, robots could be outfitted with generative AI tools like ChatGPT, resulting in more complex human-robot conversations.

As robots’ intelligence has shifted, so too have their appearances. Humanoid robots are designed to visually appeal to humans in various settings while understanding and responding to emotions, carrying objects and navigating environments. With these forms and abilities, robots can become major contributors in customer service, manufacturing, logistics and healthcare, among other industries.

While the spread of robotics has stoked fears over job losses due to automation, robots could simply change the nature of human jobs. Humans may find themselves collaborating with robots, letting their robotic counterparts handle repetitive tasks while they focus on more difficult problems. Either way, humans will need to adapt to the presence of robots as robotics continues to progress alongside other technologies like AI and deep learning.

History of Robotics

Robotics as a concept goes back to ancient times. The ancient Greeks combined automation and engineering to create the Antikythera, a handheld device that predicted eclipses. Centuries later, Leonardo Da Vinci designed a mechanical knight now known as “Leonardo’s Robot.” But it was the rise of manufacturing during the Industrial Revolution that highlighted the need for widespread automation.

Following William Grey Walter’s development of the first autonomous robots in 1948, George Devol created the first industrial robotic arm known as Unimate. It began operating at a GM facility in 1959. In 1972, the Stanford Research Institute designed Shakey — the first AI-powered robot. Shakey used cameras and sensors to collect data from its surroundings and inform its next moves.

The ability of robots to perceive their surroundings led researchers to explore whether they could also perceive human emotions. In the late 1990s, MIT’s Dr. Cynthia Breazeal built Kismet, a robotic head that used facial features to express and respond to human emotions. This predecessor to social robots opened the door for future robots like Roomba and consumer-centric inventions like Alexa and other voice assistants.

Robots took another leap forward in 2012 due to a breakthrough in deep learning. Armed with volumes of digital images, British AI expert Geoffrey Hinton and his team successfully trained a system of neural networks to sort over one million images while making few errors. Since then, companies have incorporated deep learning into their technologies, promising more possibilities for robotics.

1700s

- (1737) Jacques de Vaucanson builds the first biomechanical automaton on record. Called the Flute Player, the mechanical device plays 12 songs.

1920s

- (1920) The word “robot” makes its first appearance in Karel Capek’s play R.U.R. Robot is derived from the Czech word “robota,” which means “forced labor.”

1930s

- (1936) Alan Turing publishes “On Computable Numbers,” a paper that introduces the concept of a theoretical computer called the Turing Machine.

1940s

- (1948) Cybernetics or Control and Communication in the Animal is published by MIT professor Norbert Wiener. The book speaks on the concept of communications and control in electronic, mechanical and biological systems.

- (1949) William Grey Walter, a neurophysiologist and inventor, introduces Elmer and Elsie, a pair of battery-operated robots that look like tortoises. The robots move objects, find a source of light and find their way back to a charging station.

1950s

- (1950) Isaac Asimov publishes the Three Laws of Robotics.

- (1950) Alan Turing publishes the paper “Computing Machinery and Intelligence,” proposing what is now known as the Turing Test, a method for determining if a machine is intelligent.

1960s

- (1961) The first robotic arm works in a General Motors facility. The arm lifts and stacks metal parts and follows a program for approximately 200 movements. The arm was created by George Devol and his partner Joseph Engelberger.

- (1969) Victor Scheinman invents the Stanford Arm, a robotic arm with six joints that can mimic the movements of a human arm. It is one of the first robots designed to be controlled by a computer.

1970s

- (1972) A group of engineers at the Stanford Research Institute create Shakey, the first robot to use artificial intelligence.

- (1978) Hiroshi Makino, an automation researcher, designs a four-axis SCARA robotic arm.

1980s

- (1985) The first documented use of a robot-assisted surgical procedure uses the PUMA 560 robotic surgical arm.

- (1985) William Whittaker builds two remotely-operated robots that are sent to the Three Mile Island nuclear power plant.

- (1989) MIT researchers Rodney Brooks and A. M. Flynn publish Fast, Cheap and Out of Control: A Robot Invasion of the Solar System.

1990s

- (1997) Sojourner lands on Mars. The free-ranging rover sends 2.3 billion bits of data back to Earth.

- (1998) Furby, a robotic toy pet developed by Tiger Electronics, is released and eventually sells tens of millions of units. Furbys are preprogrammed to speak gibberish and learn other languages over time.

- (1999) Aibo, a robotic puppy powered by AI hits the commercial market. Developed by Sony, the robotic dog reacts to sounds and has some pre-programmed behavior.

2000s

- (2000) Cynthia Breazeal creates a robotic head, called Kismet, programmed to provoke emotions as well as react to them.

- (2002) iRobot creates Roomba. The vacuum robot is the first robot to become popular in the commercial sector amongst the public.

- (2003) Mick Mountz and the cofounders of Amazon Robotics (formerly Kiva Systems) invent the Kiva robot. The robot maneuvers around warehouses and moves goods.

- (2004) Boston Dynamics unveils BigDog, a quadruped robot controlled by humans.

- (2004) The Defense Department’s Defense Advanced Research Projects Agency establishes the DARPA Grand Challenge. A self-driving car race that aims to inspire innovation in military autonomous vehicle tech.

2010s

- (2011) NASA and General Motors collaborate to send Robonaut 2, a humanesque robotic assistant, into space on space shuttle Discovery. The robot becomes a permanent resident of the International Space Station.

- (2013) Boston Dynamics releases Atlas, a humanoid biped robot that uses 28 hydraulic joints to mimic human movements — including performing a backflip.

- (2012) The first license for a self-driven car is issued in Nevada. The car is a Toyota Prius modified with technology developed by Google.

- (2016) Sophia, a humanoid robot dubbed the first robot citizen, is created by Hanson Robotics. The robot is capable of facial recognition, verbal communication and facial expression.

2020s

- (2020) Robots are used to distribute Covid-19 tests and vaccinations.

- (2020) 384,000 industrial robots are shipped across the globe to perform various manufacturing and warehouse jobs.

- (2021) Cruise, an autonomous car company, conducts its first two robotaxi test rides in San Francisco.