Rapid prototyping is a process of quickly creating physical models from computer-aided design (CAD) data using fast-paced manufacturing techniques. The goal is to materialize an idea and move it from an initial concept to a working model as soon as possible.

Rapid Prototyping Definition

Rapid prototyping is an iterative approach to fabricating sample products using a computer-aided design model. Typically, it involves additive manufacturing techniques, like 3D printing.

With rapid prototyping, engineers and designers are able to iterate a prototype several times — fluidly moving back-and-forth between digital designs and fabrication — while simultaneously testing multiple versions of a sample model. This creates a near-instantaneous feedback loop and shortened product development cycles that validate a prototype’s viability on its way to becoming a finalized product.

Today, rapid prototyping is used across a number of industries, manufacturing everything from car parts and medical equipment to aerospace components.

What Is Rapid Prototyping?

Before an item is set on a store shelf, it starts as a prototype that undergoes months of development and experimentation. But thanks to 3D-printing technologies, rapid prototyping reduces that lifecycle to a fraction, with first iterations possible in a matter of hours.

“Rapid prototyping lets you turn ideas into something tangible, fast,” Paul Chow, chief technology officer and co-founder of tech review platform 3DGearZone, told Built In.

Since rapid prototyping allows for quick iteration, designers and engineers can test sample models, experiment to see what works then tweak the design before investing heavily in final production.

“Rapid prototypes might not be as strong or polished as final products,” Chow said. “But that’s the beauty — you’re figuring things out early on, before you commit to big manufacturing runs.”

Patrick Faulkner, a lead engineer at mechanical components manufacturer Accu, said that, “at its heart,” rapid prototyping is generative, and its function is to enable quick testing.

“This rapid method of information gathering shortens the product development cycle and in turn the whole project due to the ability to incorporate changes based on data and feedback from the objects produced in each round,” he said.

How Does Rapid Prototyping Work?

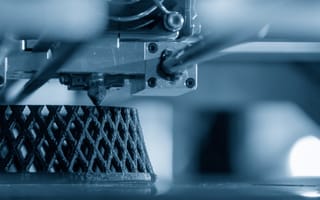

All prototypes start as a digital file of a product design. This serves as a blueprint that instructs a 3D printer on how to build a structure one layer at a time.

Depending on the manufacturing approach, a heat source or liquid binding agent may be used to fuse materials together to print a three-dimensional model. As one layer cures, another is applied on top until the design is fully materialized.

During post-processing, final touches, like removing support structures and surface finishing, are completed before sending the prototype off for testing, where it’s evaluated for functionality, form and fit.

Once feedback is collected — from in-house teams, partners, focus groups, stakeholders and end users — proposed changes are integrated into a new iteration of the design, and the process repeats until the prototype is finalized.

“Rapid prototyping is an ongoing cycle of designing, printing, testing and iterating,” said Evan Fisher, a materials scientist and 3D model manager at Formlabs. “3D printing can deliver a prototype in just a few hours, giving designers and engineers the opportunity to run tests, see how the design would work ... and restart the cycle until the prototype is perfect.”

Advantages of Rapid Prototyping

Turning out prototypes at hyper speeds comes with its share of benefits.

Speed

Quick iteration and prompt development cycles reduce time-to-market when building a prototype, from a matter of months to weeks, according to the LA New Product Development Team, with the first iterations 3D printed in as little as a few hours.

Cost Effective

The pace of rapid prototyping grants quick access to testing, where faulty, dead-ends discovered during the design or engineering phase of a prototype can be ruled out before deeper investment in materials, labor and machinery are made.

Better Designs

The quick pace and relatively low cost of rapid prototyping allows designers to create and test multiple iterations of a design side-by-side, making way for creative experimentation as well as refinement. High-speed iteration leads to early feedback rounds, which can cue designers to identify and address potential issues sooner rather than later, leading to more informed decisions making.

Reduced Risk

With prompt validation and concept testing, rapid prototyping helps mitigate risks associated with product development, such as market acceptance and technical feasibility.

Disadvantages of Rapid Prototyping

Given the novelty of the technology, engineers are still working out some kinks as rapid prototyping finds its way into mainstream manufacturing.

Accuracy

Rapid prototyping prioritizes speed over accuracy. And while high-fidelity mock-ups are possible, it’s important to note that not all rapid prototyping methods are created equal. This is why designers may opt for more precise 3D printing practices, like stereolithography or material jetting, when fabricating a function-focused product.

Design Limitations

While a 3D-printing machine may seem to be able to fabricate out of thin air, it’s not guaranteed that every intricate detail of a complex CAD design will survive professional-grade manufacturing methods by the time the prototype makes it to the final product stage.

Limited Materials

The range of materials available for rapid prototyping may not always meet the specific requirements of a given project. Certain materials, for example, may lack the desired strength, flexibility or heat resistance required of a final product. Material choice may also face further restrictions when considering specific manufacturing techniques as well as a project’s budget.

Initial Cost

Initial setup costs for rapid prototyping equipment can be high. Professional-grade FDM 3D printers, for example, start at around $2,500. Those with a larger build are about $4,000, while the most advanced industrial FDM printers are upwards of $10,000.

Low Resolution

Depending on the rapid prototyping method used, surface finish and resolution may not always match professional-grade industry standards. This may turn into additional post-processing steps to achieve the desired quality in surface finish, resolution quality and sturdiness of a prototype.

Prototyping vs. Rapid Prototyping

The main difference between prototyping and rapid prototyping is exactly as you might have guessed — speed.

Traditional prototyping typically follows a structured approach, where parts are sent back and forth for molding, tooling and so on over the course of a few months to a year.

But with rapid prototyping, additive manufacturing methods can iterate test models in a matter of hours, resulting in accelerated development cycles and near-instantaneous feedback loops. Thanks to new-age technologies, largely credited to various 3D-printing techniques, designers and engineers can ask specific questions about a sample product, which can be promptly generated for testing and amended, director of advanced technology at Rockwell Automation Kyle Crum explained.

“The core difference with rapid prototyping is focus,” Crum said. “Samples are developed with the sole intent of answering questions related to the current [technology readiness levels] before progressing to the next stage. Extra effort, while commendable, doesn’t count.”

The ability to rapidly produce new-and-improved versions while simultaneously testing other iterations of a product shortens pre-production lifecycles. This enables creators to think, design, test, learn, iterate — and repeat in perpetuity, Crum said, until they get it right.

Additionally, traditional prototypes are often made with slower, subtractive manufacturing methods that are typically outsourced rather than in-house additive ones that tend to be more precise as well as cost efficient in the long run, Fisher said.

“This can take weeks for new molds or prototypes to come in, lengthening the design process and stifling innovation,” he added. “Rapid prototyping creates a faster design process, enabling more iterations, simultaneous testing and refinements in less time than when outsourcing prototypes.”

Types of Rapid Prototyping

Proof-of-Concept Prototypes

Physical concept models demonstrate the feasibility and core functionality of an idea. Product designers use working proof-of-concept prototypes to validate assumptions, troubleshoot technology and allow for low-risk exploration at an early stage in design development.

Looks-Like Prototypes

Looks-like prototypes are visual representations of a final project, sans functionality. By presenting a superficial model, designers gain insight into how end users interact with a product in order to make adjustments accordingly before building out a product in full.

Works-Like Prototypes

A works-like prototype simulates the functionality and behavior of a final product. These models contain all core technical components — mechanical, electrical and thermal systems — in order to validate a product’s performance and design, and are not concerned with looks or feasibility.

Engineering Prototypes

Engineering prototypes are built specifically for testing and evaluation purposes. These minimal iterations share likeness of the final product in both appearance and functionality, but they never leave the lab. They are tested for structural integrity, functionality, performance and manufacturability to help verify final design decisions before moving into production.

Examples of Rapid Prototyping

Stereolithography (SLA)

Stereolithography is an additive manufacturing technique that uses a UV laser to cure liquid resin into solidified layers. According to Formlabs, this method offers the quickest speed and highest resolution value with accuracy of all 3D printing technologies — making it a popular choice for rapid prototyping. It’s sometimes called photopolymerization or resin 3D printing.

Selective Laser Sintering (SLS)

This type of additive manufacturing 3D prints objects using a light source, like lasers, to bind powdered materials together, layer by layer. This method differs from traditional manufacturing methods in that it can create complex geometries and functional parts without molds or machining.

Fused Deposition Modelling (FDM)

Also known as material jetting, this 3D-printing method extrudes thermoplastic filament through a nozzle to create three-dimensional objects, as instructed by a digital design. It’s one of the most common 3D printing techniques, especially among hobbyists.

Powder Bed Fusion (PBF)

In powder bed fusion, a heat source — like a laser or electron beam — melts powders together, as the build plate drops and fresh material is dispensed atop the previous, fused layer. Typically, this particular 3D printing approach works with metal and polymer-based powders, and is used in industrial settings. It also goes by selective laser sintering, selective laser melting and electron beam melting.

Sheet Lamination

Sheet lamination bonds layers of material — such as paper, metal foil or plastic — together and cut to shape with a laser or blade. Materials may be fused together using a variety of approaches, like adhesives, lasers or ultrasonic welding. For rapid prototyping, this method is ideal when creating large models with limited resources on quick turnaround and at low cost.

Digital Light Processing (DLP)

Digital light processing exclusively works with liquid photopolymers, where entire resin layers are cured at once using a digital light projector. This method is known for producing products in high-resolution with smooth surfaces, making it a standout choice for rapid prototyping jewelry, dental molds, toy figurines and consumer electronics.

Binder Jetting

Binder jetting creates three-dimensional prototypes that use a printhead to selectively dispense a liquid binding agent over a build platform covered in powder. Once dried, a new layer of powder is disbursed to repeat the process. Binder jetting differs from powder bed fusion as it does not use a heat source. It’s a cost-effective approach to rapidly produce functional prototypes, whether made out of foundry sand, ceramics, metals or composite materials.

CNC Machining

Computer numerical control (CNC) machining is a subtractive manufacturing process where material is removed from a solid block to create a part or prototype. While it’s not as fast-paced as 3D printing, CNC machining offers high precision and versatility, making it a go-to rapid prototyping method when intricate details or specific material properties are required.

Vacuum Casting

This rapid prototyping technique creates a silicone mold from a master model, where liquid casting material is poured into in order to produce multiple replicas. It’s an efficient method for quickly producing small batches of prototypes with high-quality surface finishes and material properties, suitable for testing and validation purposes.

Rapid Injection Molding

Rapid injection molding uses quick-turn tooling to produce prototypes in relatively short lead times. By intentionally using cheaper molds and easy-to-machine materials, like aluminum, it allows for the creation of functional prototypes with properties closely resembling those of final production parts in order to test and validate designs prior to full-scale manufacturing.

Frequently Asked Questions

What is an example of rapid prototyping?

3D printing, like stereolithography or fused deposition modeling, and CNC machining are two common methods of rapid prototyping.

What is the difference between rapid prototyping and 3D printing?

Rapid prototyping is a broader term inclusive of various techniques for iterating product models — which could also be accomplished through CNC machining or injection molding. 3D printing is one approach to the manufacturing procedure.