Formlabs solved one of the most vexing problems of its 3D printers in 36 hours.

That problem? The need for a human to remove finished parts from the printer and reinsert the platform, or the surface where the object is printed, before starting a new print job.

Removing finished parts and reinserting the platform takes less than two minutes total. But this time eventually adds up, and the need for a human helper means printers can only be run during working hours. In addition to increasing convenience, automating this process would enable companies creating components in the aerospace, automotive, dental and medical fields to print around the clock and further make mass production via 3D printing possible.

Formlabs has a culture that encourages experimentation and collaboration, especially between individuals from different disciplines.”

The aha moment for a solution to this issue came at a company’s annual hackathon, where Senior Mechanical Design Engineer Sean Oh and his team decided to delve into possible ideas for a successor to Form Cell, an existing company product created to fill a similar void.

“At the hackathon employees are encouraged to create anything they want, and my team took this opportunity to make something completely different from the Form Cell,” Oh said. “We built a modular solution that automated key parts of a single 3D printer as opposed to a whole fleet.”

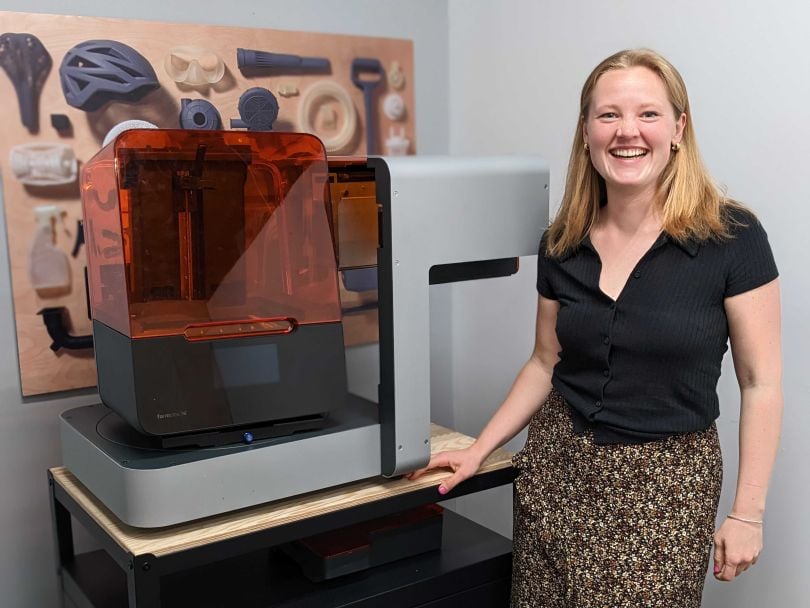

Enter Form Auto, a hardware extension for its 3+ 3D printer that adds a quick-release mechanism to enable parts to be dropped into a box so printing can continue. The extension debuted in January at CES 2023, where it was well-received by customers who were excited by the possible efficiency gains.

“This increases any Form 3+ user’s print capacity significantly, making it easier to scale without adding complexity or labor,” Product Marketing Manager Elena Austras said.

Ask Questions, Take Risks

When designing the Form Auto, Oh and his team initially set out to build a newer version of a large industrial 3D printer complete with a robot arm, aka the Form Cell 2.0. A sequel to that 3D printer would have satisfied the automation objective. But it wouldn’t have met the goals of affordability and scalability.

Eventually, the team decided to scrap the idea of a sequel altogether. “The more work we put into the design, the less it felt right, even though it met all the requirements and would execute its function well,” Oh said.

The team went back to the drawing board, but it was blank. Eventually, they accepted that they didn’t know what they didn’t know and turned to their customers — and competitors — for inspiration.

“We went to tradeshows to talk and learn from competitors and customers alike and we rehashed market and customer data analysis in every way possible,” Oh said. “We questioned our assumptions and strove for more. Thus, Form Auto was born.”

Building Buy-in Across the Business

As a product marketing manager, Austras quarterbacked the go-to-market strategy, working closely with the product manager for Form Auto to determine positioning and messaging. In addition, Austras collaborated with nearly every department across the company and trained customer-facing teams and external resellers.

“This is one of the best parts of my job,” Austras said. “Seeing how everything comes together is the magic of any product launch.”

Working with so many teams can be a recipe for disorganization and delays. That’s not the case at Formlabs, though, which has maintained a culture of close-knit collaboration despite having a headcount of nearly 1,000 employees.

“Stakeholder buy-in and brainstorming are critical in setting collaboration in the right direction,” Austras said. “These initial meetings are foundational and present an opportunity to bring team leads up to speed, get them excited and have a brainstorming conversation about how each team can contribute to making the product launch a success.”

Of course, Austras was careful to point out that launching a new product isn’t all smooth sailing, especially when it comes to hardware and the world’s seemingly never-ending supply chain strain. Flexibility was key in dealing with these issues, as was building in buffers into her project timeline to account for interruptions that couldn’t be planned for. When these unexpected events arose as they inevitably do, Austras found it important to trust her teammates to solve the problems they could while working hard on the issues she could tackle and remaining positive.

Product Development = Professional Development

Form Auto will not be the last product Oh and Austras develop and bring to market at Formlabs. That said, their future work at the company will be directly informed by what they learned working on this product.

For his part, Oh now has a more complete understanding of the product development lifecycle, from market analysis to fulfillment logistics. This holistic viewpoint has also given him a greater appreciation for the work of his colleagues across the business. He also grew to learn and love a relatively new piece of CAD software called Onshape. “Onshape was able to show me what a modern CAD platform could really do and exposed me to features I never imagined I would ever want, but now absolutely need, he said.”

On Austras’ end, working with so many different teams helped her develop a deeper understanding of Formlabs’ customer segments and sharpen her communication skills. On the communication front, she found that being more assertive and explicitly stating her needs, expectations and positions left less room for miscommunication with leads from other teams. Developing this skill was a balancing act that required a willingness to share ideas without holding onto them too tightly so as to disrespect a dissenting point of view.

“Being assertive helps build strong relationships and improves cross-functional work.”

As for what’s next?

“I am always enabled to challenge the status quo and take creative risks,” Oh said. “I firmly believe that Formlabs is a place of opportunities and where ambitions can be realized.”