3D printing has made it easy to quickly create everyday items out of plastic, houses out of concrete and even food out of edible filaments. But there’s a race within additive manufacturing to develop high-throughput printers that work with a different kind of material: metal.

What Is Metal 3D Printing?

Metal 3D printing is an additive manufacturing process that prints metal-based materials (such as aluminum, stainless steel, titanium, copper and nickel) to create three-dimensional structures.

Tech startups, researchers and manufacturers turn to metal 3D printing to print fully functional prototypes and custom, end-use parts on quick turnaround with total design freedom and high precision. Depending on the project, metal 3D printing may even serve as a low-cost alternative to traditional methods.

What Is Metal 3D Printing?

Metal 3D printing is an additive manufacturing process that creates physical objects from a digital model out of metal-based materials. As with any other material, metal prints are built one layer at a time using a variety of techniques that differ in the way they fuse metal feedstocks, often in the form of powder.

“Metal additive manufacturing requires higher power energy sources … and is much more industrial in nature than other forms,” Patrick Boyd, marketing director at EOS North America, told Built In.

As such, 3D printed metal is lightweight, durable and more flexible than traditionally manufactured metals (the strength and quality can match conventionally made parts).

Metal 3D printers enable in-house production of on-demand parts, which reduces supply-chain risk and quick replacement for high-wear applications.

“Humans have essentially been shaping, grinding, drilling and casting objects in the same manner for thousands of years,” Boyd said. And while traditional manufacturing methods aren’t about to be replaced by metal 3D printing, this technique “has removed many limitations of traditional manufacturing,” he added. And with limitless design freedom, “objects previously impossible to create from metal, whether one or many pieces joined together, are now possible.”

How Does 3D Printing Metal Work?

Metal 3D printing begins with a computer-aided design model. These digital mockups are spliced into cross sections, and feed the printer instructions on how to execute each layer.

From there, the actual build process initiates. Generally speaking, this starts with spreading a thin layer of metallic powder across a build platform. A high-energy source — laser, electron beam or ultrasounds — then selectively melts the powder according to the CAD-file blueprint, fusing the metal particles together.

These temperatures often exceed 1,000 degrees celsius and require heavily controlled environments, said Nasim Anjum, a mechanical engineer and PhD candidate researching composite materials at Binghamton University, State University of New York. In a vacuum chamber, for example, gasses like nitrogen or argon are used to prevent material oxidation.

After each new layer fuses to the previous one, the build tray lowers, and a fresh coat of powder is applied. This process repeats until the entire part is formed. Once complete, support structures are removed from the part, which typically undergoes additional post-production steps, like heat treatment or machining, to optimize desired properties, aesthetic and finish.

“Building parts layer by layer uses only the necessary amount of material,” added Anjum, who is conducting his research in Binghamton’s Nanomechanics Laboratory led by Professor Changhong Ke. When there is excess material, it’s often collected and recycled into the next project. This not only minimizes waste and reduces material costs, but also “promotes more sustainable manufacturing practices.”

How Is 3D-Printed Metal Used?

As a relatively new technology, metal 3D printing has been slowly making its impact on a number of industries. Every year, the variety of metals expands and novel approaches are expanded on or invented, “enabling designers to produce complex geometries and high-strength parts that traditional polymer 3D printing methods cannot achieve,” said Patrick Faulkner, a lead engineer at Accu.

The way metal 3D printing can handle high melting points with precision has changed the way designers look at producing prototypes and small runs of parts otherwise impossible to create with conventional, subtractive processes, Faulkner added. “This process results in [prints with] superior mechanical properties.”

Aside from speeding up the overall product-development cycle and fast-tracking the time-to-market, metal 3D printing enables companies to create tools and reproduce components in-house while significantly cutting waste.

Prototyping and Product Development

Engineers and designers use metal 3D printing to create both concept models and functional, high-fidelity prototypes. Rapid iteration allows a product’s form, fit and function to be tested at an accelerated pace, shortening the timeline to mass production. This enables rapid prototyping, shorter product life cycles and a quick time-to-market.

Manufacturing

Metal 3D printing is most often used to create high-precision prototypes and lightweight, custom parts for low-volume production runs. It can also produce molds for processes like injection molding and casting, and fabricate tailor-made jigs, fixtures, tooling and spare parts in house. In some cases, metal 3D printing beats traditional manufacturing methods in its ability to create semi-hollow parts with like-for-like strength-to-weight ratios in one go and complex, intricate shapes “that were previously impossible to produce,” Faulkner said.

Aerospace

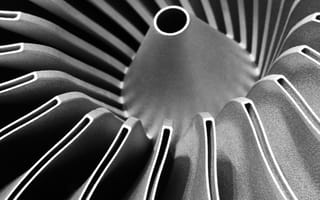

Manufacturing lightweight, custom components that can withstand extreme environments is what lands 3D printing metal in the aerospace industry. Currently, engine parts, airframes, turbine blades, field nozzles as well as satellite launch vehicles in their entirety are being 3D printed by innovative startups inventing the tech as they go.

Developing metal 3D printers that can be used in outer space, “where traditional metal part manufacturing processes are more challenging,” is also in the works, Anjum said, noting the recent deployment of Airbus’ polymeric printers to the International Space Station.

Automotive

While traditional manufacturing methods remain the standard, 3D printing metal is making waves in the automotive industry with prototyping and fabricating individual parts. It’s come a long way from car cosmetics, like gear sticks and decorative logos, to printing the entire chassis, suspension system and exhaust components of Czinger Vehicles’ 21c as well as BigRep’s fully 3D-printed, electric motorcycle, NERA.

Medical and Dental

In the medical field, metal 3D printing is used to create bio-compatible implants, prosthetics and dental crowns, bridges and implant bars with precise fit specific to the patient — even if that patient is a gorilla, like Gladys, who received the world’s first titanium, 3D-printed cast.

And while metal is a foreign material to the body, researchers are inventing ways to decrease the likelihood of rejection and infection, including antimicrobial 3D-printed metal for use in regenerative medicine as surgical scaffolding.

Marine

Metal 3D printing has found a way into nautical applications, primarily using titanium and stainless steel to produce boat propellers, hydraulic systems, rudders and foils as well as halyard trays, boat shafts, mounting flanges and custom hull components. In 2024, the United Kingdom’s Royal Navy acquired two 3D metal printers to handle repairs and print critical components that are no longer in production.

Methods of 3D Printing Metal

Below are 3D printing techniques that are compatible with metal materials, beginning with the two most common categories — powder bed fusion and direct energy deposition.

Powder Bed Fusion

Powder bed fusion selectively fuses powder particles together using a heat source, such as a laser or electron beam. As a recoater blade spreads a thin layer of powder material across a build platform, the laser traces out a cross section, instantly melding the material together. This step is repeated layer by layer, with a fresh coat of powder until the model is built to completion. Known for its capability to fabricate complex geometries and intricate details with high precision, powder bed fusion is actively being used to produce lightweight aerospace components and biomedical implants.

Direct Energy Deposition

Direct energy deposition uses thermal energy — such as a laser, electron beam or plasma arc — to simultaneously melt and fuse metals as they’re extruded from a nozzle. A multi-axis robotic arm deposits molten metal feedstock (in the form of a powder or wire) at any angle, making direct energy deposition useful for performing repairs or adding material to existing components. This technique is often performed within a vacuum at reduced oxygen levels, and is especially useful for creating large-scale projects of near-net shape.

Material Extrusion

Material extrusion is typically reserved for thermoplastics and polymers, but can incorporate metals via filament mixtures of metal powder and a binder. Similar to DED, this technique uses a heated nozzle that directly extrudes spooled filament in a continuous stream onto a build tray. The robotic arm it’s attached to moves the printhead in a way that outlines each cross section of the print, as instructed by a CAD model. With metals, material extrusion is likely to require additional post-processing steps, like debinding and sintering.

Binder Jetting

Binder jetting adheres materials together by selectively depositing liquid binding agents onto a thin layer of powdered metal. This method, known for its high throughput and quick delivery, is unique in that it does not require a heat source. Instead, glue is dispensed from an oscillating printhead above a build tray that is lowered, then covered in a fresh layer of powder with each new cross section of the structure. Metal parts made from binder jetting typically undergo further production, such as curing and sintering, to optimize structural integrity and enhance built-in material properties.

Sheet Lamination

Sheet lamination joins metal sheets together using a variation of methods, from welding and heat to pressure, adhesives and even sound. A laser or blade cuts each layer to the desired shape, then fused or bonded to the previous layer until the design is complete. Excess material surrounding the print acts as structural support that’s removed during post-production and recycled for the next project. This process is relatively quick, cost effective and can be conducted at low temperatures. But these prints, which can also be made out of paper or plastic, are typically for aesthetic use only and not structurally sound or fully functional.

What Metals Can Be 3D Printed?

Some of the most common metals used in 3D printing are aluminum, stainless steel, titanium, copper and nickel-based alloys. Other popular choices include cobalt, tungsten and tool steels. These metals are processed in different forms as powder, wires, filament-mixtures and sheets.

Metals are matched to projects based on several conditions, from wear and corrosion resistance to strength and density. Depending on the intended use case, a metal’s electrical conductivity or thermal properties may be important to factor in, as well as biocompatibility.

3D printing precious metals — like gold, platinum, palladium and silver — is doable, but typically limited to jewelry- and watch-making, given their expensive price tags.

Frequently Asked Questions

Can you 3D print metal?

Yes; metal can be 3D printed using a variety of methods, the most prominent one being powder-bed fusion. The two most common techniques are selective laser melting (SLM) and electron beam melting (EBM).

How does 3D printing metal work?

Generally speaking, metal 3D printing works by spreading a thin layer of metallic powder across a build tray, which is then selectively melted by a high-powered laser or electron beam as instructed by a digital design. This process is repeated layer by layer until the entire part is formed. All metal 3D printing methods differ based on how each type of printer joins metal-based materials and what form those materials come in, whether that’s powder, wire, filament mixtures or sheets.

What types of metals can you 3D print?

The most common metals used in 3D printing are aluminum, stainless steel, titanium, copper and nickel-based alloys.

What is the strongest material you can 3D print?

Stainless steel is the strongest 3D-printed metal, with a tensile strength of 1,103 megapascals, according to Xometry.