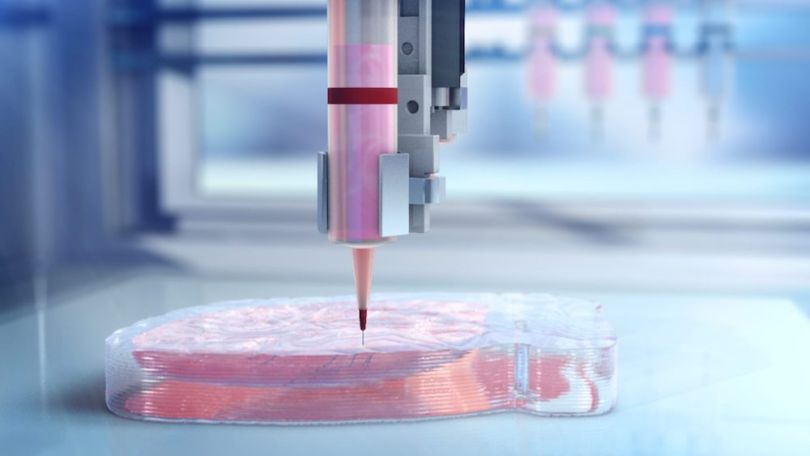

To some extent, bioprinting has what they call in Texas an “all hat, no cattle” problem. The process and its products both tend to grab the eye, but the practical applications have so far been limited. A couple of recent milestones, though, are helping change that. The twin achievements — a new bioprinting process that clears a longstanding structural hurdle, and the creation of a “mini-heart” — represent noteworthy steps toward the ultimate goal of 3D-printing organs for humans.

“If you go on the Internet and see stuff about bioprinting, you’ll see things that look cool but almost never show anything with an actual function” said Adam Feinberg, a researcher at Carnegie Mellon University whose team developed a new bioprinting method. “We show that we can actually build things that don't just look cool.”

CHARTING THE FUTURE OF 3D BIOPRINTING

THE NEED FOR STRUCTURE

For the uninitiated, bioprinting essentially uses the same layer-by-layer additive construction method as traditional 3D printing hardware. But instead of, say, layering metal powder to build small gears or engine parts, bioprinters layer living cells and/or polymer gels to build tissue-like forms.

In theory, collagen is an ideal bioprinting material because it’s the most abundant protein in the human body.

“Collagen has been the holy grail of bioprinting,” Feinberg said. “It’s the primary structural component of just about every tissue and organ in the body.”

The catch: It’s also extremely difficult to use, collapsing into a puddle in most bioprinting attempts unless heavily modified.

But Feinberg and his team developed a new approach, dubbed FRESH, that provides a temporary structural support that allows collagen time to solidify. The support material can be melted away once the collagen is solid and has the mechanical strength it needs to survive structurally.

“We basically figured out how to print it at the highest resolution and fidelity that has ever been possible for collagen,” Feinberg said.

With the new technique, the team was able to print functioning heart valves and a small beating model of a human ventricle, capable of conducting the electrical signal around the heart that coordinates contraction. “It’s not ready to be implanted into a person, but the proof of concept that we can 3D-print heart muscle is there,” Feinberg said.

THE TECH THAT DRIVES THE SCIENCE

The researchers achieved their breakthrough thanks in part to some self-customized printer tailoring that should make DIY 3D hobbyists smile.

The lab spent years developing its own customized extruders, used to deposit cells and biological materials with a syringe. It then integrated those extruders onto relatively low-cost LulzBot printers, which they purchase from a company called Aleph Objects, replacing the plastic extruders with the hydrogel-friendly syringe extruder system.

“We're now at our fourth-generation open source syringe extruder, which you can add to any low cost desktop plastic 3D printer to turn it into a bioprinter. And it provides, I would argue, equal or better performance for FRESH printing than you get from the $250,000 machines,” Feinberg said.

While high-dollar models may offer more precise motion control or multiple extruders (Carngie Mellon’s has only three), Carnegie Mellon’s open source approach affords “extremely high performance for very little money.”

Like previous iterations, both the current extruder design and the full printer design were made open source, and therefore are widely accessible. “We now have people on every continent except Antarctica using our printer design,” Feinberg said.

THE MAKING OF A MINI-HEART

Feinberg also provides scientific guidance for a Chicago biotech startup called BIOLIFE4D that achieved its own heart-related breakthrough. This one doesn’t skimp on wow factor: It’s a 3D-bioprinted mini-heart.

Here are the basics of how they did it: Researchers re-engineered blood cells into stem cells, then “differentiated” the stem cells into the many various cardiac cells that exist. Those cells, along with the company’s proprietary bioink, allowed the team to print a “mini human heart” complete with ventricles, valves, four chambers — the works.

The lab biofabricated the heart using a 3D Inkredible Plus printer from Swedish company CELLINK, a leader in the bioprinting sphere.

“While our mini-heart is not designed as a viable transplant option and doesn’t incorporate the full function set of a native heart yet, it represents a significant milestone,” said Ravi Birla, chief science officer at BIOLIFE4D.

In the short term, BIOLIFE4D is fine-tuning its process with the goal of bringing the mini-heart to market as a test model that researchers can use to study heart ailments.

“At this point, we’re focused on the process,” he said. “From here, it’s a matter of scaling up and tweaking the functionality on the way to a full-sized heart.”

THE 3D PRINTING IN MEDICINE MARKET

While bioprinting’s potential in terms of pharmaceutical drug testing and organ transplants has yet to fully mature, more conventional 3D printing techniques have already provided sizable benefits for medical device manufacturing, surgical training and other healthcare needs. Here are a few companies making good on 3D printing’s promise in medicine.

ANDIAMO

ORTHOTICS & PROSTHETICS

In terms of healthcare, 3D printing has perhaps most noticeably impacted orthotics and prosthetics. The technology has allowed companies like London-based Andiamo 3D to quickly make durable gaiters, braces and other orthotics at relatively low costs. Co-founders Samiya and Naveed Parvez started Andiamo after experiencing the industry’s shortcomings firsthand. Their late son was quadriplegic and needed braces to eat properly and sit upright, but by the time his gear arrived, he often had outgrown it. Andiamo 3D uses a combination of artificial intelligence, data analysis and 3D printing to build their wares.

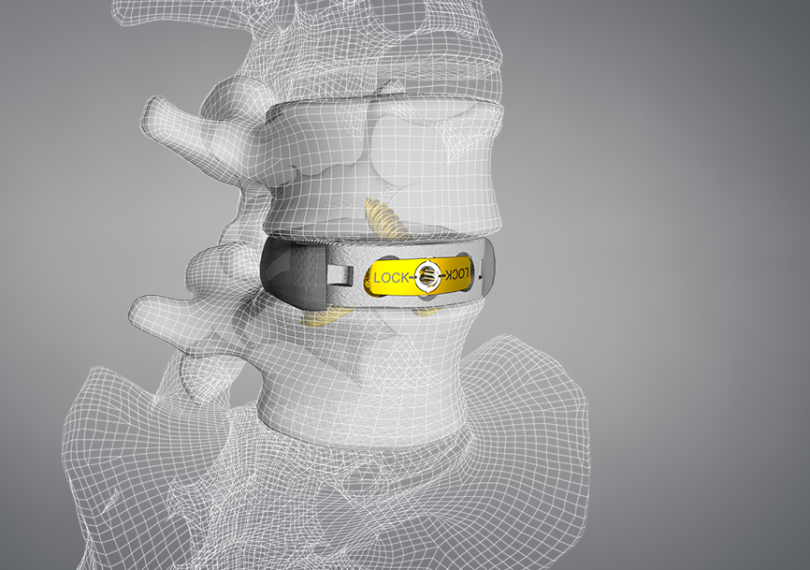

CORELINK SURGICAL

GROW A SPINE

When the annual North American Spine Society meeting convened in Chicago this September, more than two dozen of the exhibitors were companies that incorporate 3D printing into their practice in some fashion — a reflection of how deeply additive manufacturing is now ingrained in spine care. Among the notables are 3D Systems, which fabricated the first FDA-approved titanium implant and was co-founded by the man who patented stereolithography, and CoreLink Surgical, a St. Louis-based maker of spinal devices and implants. Many of the latter incorporate a proprietary process dubbed Mimetic Metal, laser-based titanium-alloy 3D prints that mimic human bone.

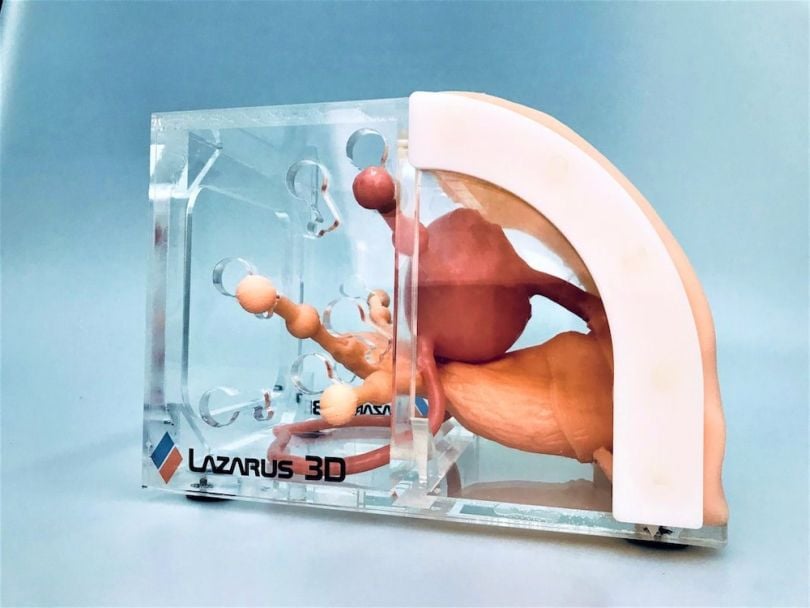

LAZARUS 3D

BETTER MEDICAL TRAINING

Everything from gaming tech to virtual and augmented reality has impacted how some doctors train and prepare for surgical procedures. Add 3D printing to the list. Companies like Houston-based Lazarus 3D are running with additive manufacturing’s capability to produce realistic, soft-polymer silicone models of human tissue and organs. Its models have been used in institutions like Baylor University’s urological education department to help train medical students.

LIGHTFORCE ORTHODONTICS

BRACKET CHALLENGE

3D printing can be used to print all manner of dental tools, including crown and bridge models, night guards, bonding trays, drill guides and dentures. It has orthodontic applications, too. One recent milestone comes courtesy of LightForce Orthodontics. The Boston area startup, founded by a Harvard-trained orthodontist, recently unveiled what it touts as the first customized 3D-printed brackets — the small pieces that cement to teeth and connect ties in braces. Brackets made with the system are molded to custom-fit the shape of each tooth.

ALLEVI

SKIN IN THE GAME

Researchers have demonstrated that it’s possible to 3D print flaps of skin, even with a handheld printer. That’s a potential game-changer when it comes to skin grafts for burn victims. We say “potential” because 3D-printed skin has yet to graduate beyond the research labs for several reasons. Not only does it lack a fully functioning vascular network, there also are roadblocks in the stem cell research that’s necessary to produce hair follicles and sweat glands. In the meantime, companies like Allevi are helping keep researchers supplied with the material necessary to (possibly) facilitate the next breakthrough. The Philadelphia-based bioprinter maker also sells bioink kits, including a skin bioink kit that purportedly “provides the ability for the first time ever to create in a simplistic standardized fashion dermis layers and epidermis layers using low concentrations of pure collagen.”

WHAT’S NEXT?

ROADBLOCKS AHEAD

As noteworthy as BIOLIFE4D’s and Carnegie Mellon’s individual efforts are, we’re still a long way from realizing that most headline-grabbing of ambitions: a viable 3D-printed heart for transplant. Generating cells is very time-consuming and costly, and a complete heart would require a lot of cells — between two and three billion, according to Feinberg.

“It’s a really high bar,” he said.

Scientists are also still sorting out how to best use bioreactors to mature tissues once they’re created.

“When you first print something, it’s really not done,” Feinberg said. “You have to ensure the organ cells can properly interconnect and function before you can ever think about carrying it forward.”

“People should be excited and enthusiastic about what we’ve achieved, but also realize this is a step along the path,” he added. “And it’s a difficult path.”

Researchers will also have to keep tweaking individual components of the bioengineered heart to eventually reach a point where the organ can properly function throughout a patient’s life, Birla noted.

“It’s impossible to say exactly how long this will take, but we have been making rapid advancements and hope to be able to begin to push this technology to the market in the next few years,” he added.

In the meantime, there are simpler but still effective cardiac bioprinting interventions that can likely be achieved along the way. In the future, Feinberg said, small patches of functional tissue could be bioprinted to replace dead cells after a heart attack.

“That’s probably all a lot of people need, and it’s definitely advantageous over a full transplant.”

Procedures like that, he added, represent “the low hanging fruit that will actually provide the maximum benefit to people with heart failure.”

Feinberg’s scaffolding achievement holds promise for other medical fields as well. He’s working on using it to combat volumetric muscle loss, which is often caused by traumatic injury or tumor growth. The implanted material “would serve as a bridge to heal wounds larger than your body can normally heal,” he said. “It basically recruits your own immune cells to help regenerate muscle.”

Other possible uses are no less impressive. They include 3D-printed collagen matrices to build tracheas, and printing mammary growth tissue to study how breast cancer cells migrate from inside ducts to outside ones, in the process becoming life-threatening.

Should they become a reality, 3D-printed organs can potentially save thousands of lives and stem the organ donor crisis that has been ongoing in the United States for years.

Over at least the last three decades, the number of people waiting for a transplant has risen at a far higher rate than the number of donors, according to the Health Resources and Services Administration. In 1991, more than 23,198 people were on the transplant waiting list, and there were 6,953 donors. In 2018, the list had ballooned to 113,759, yet donors numbered only 17,554.

But the field of 3D-printed organs has also opened up a variety of ethical issues, including access.

“It’s not just if we can do it,” Feinberg said. “It’s also, How do we do it as something the healthcare system can absorb? If only the people who can afford to take a SpaceX trip to the moon are the same ones who can afford a bioprinted heart, that’s a problem.”

That potential issue deserves scrutiny, according to BIOLIFE4D’s Birla.

“Our goal is to have this technology available to the people that need it the most and provide a life-saving option for these patients,” he said. “As with any new technology, it should be monitored so it’s not exploited for the wrong purposes.”

AN ETHICAL APPROACH

For Dr. Brendan Parent, director of transplant ethics and policy at NYU Langone Health’s division of medical ethics, the issue of access is important but not unsolvable. Nonetheless, he said, additional ethical questions exist and should be kept in mind as the technology and science mature.

For example, will access to viable 3D-printed organs — should they become available — risk reinforcing bad health habits?

“Right now, this is the stuff of science fiction,” he said, “but I wouldn't be surprised if we get to a point where [organ bioengineering] is actually pretty good, why not drink your liver into oblivion if you can just grow a new one?”

A far nearer-term consideration relates to testing these innovations on people. Because scientists can learn only so much from animal modeling, bioprinted organs would eventually need to go further up the testing ladder — potentially to brain-dead humans on life support who had previously consented to serve as test models. But those are also the same donors whose vital organs could be harvested to save other lives already, right now.

“That then might make this testing impossible because other important organs have been removed to demonstrate the efficacy of the engineered organ,” Parent said.

The fact that no international regulatory structure exists to universally tackle such challenges only makes them more difficult.

Even so, bioengineered organs represent a better option compared to what’s called “xenotransplantation,” which Parent describes as an attempt to “engineer animals to be more human-like” for organ transplant purposes.

“Anyone with a conscience will acknowledge that we still have to respect at least limited rights of animals, and it's not a perfect solution to expand the factory farming problem to include animal organs,” he said. “And if we can grow organs in the lab that are tailored to individuals, and derived from our cells, we hopefully can deal with the immune rejection issues better.”

Indeed, given the functional metrics researchers have hit and the potential for major positive impact, now seems like a time for optimism rather than trepidation.

“We really tried to raise the bioprinting bar, from what had been mostly potential and enthusiasm for what it might do, and show that we can now actually do new things can — and do them in a way that no other technology can,” said Feinberg.

Images via company sites and social media. Illustrations via Shutterstock.