It started in 2004, when two researchers from the University of Manchester took a strip of adhesive tape to a chunk of pencil lead. What they revealed was graphene, a one-atom-thick sheet of carbon arranged in a honeycomb pattern. It was incredibly thin and light-weight — but also stronger than steel, more conductive than copper and incredibly elastic.

Graphene Definition

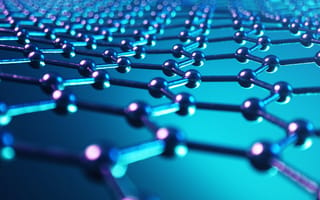

Graphene is a one-atom-thick sheet of carbon atoms arranged in a flat, hexagonal pattern. Despite its thinness, this material is known for its exceptional strength, flexibility, high conductivity and thermal properties, making it useful across a wide range of technologies — from batteries to medical sensors.

That simple experiment jump-started a new era in materials science. The two researchers, Andre Geim and Konstantin Novoselov, won the Nobel Prize in Physics in 2010. And graphene quickly became known as a “wonder material,” with the potential to transform industries ranging from manufacturing to biomedicine. Now, researchers around the world are using it to make everything from longer-lasting batteries and flexible touchscreens to solar cells and medical implants. Its discovery also inspired the search for other two-dimensional materials, opening up an entirely new frontier of nanotechnology.

“Graphene marks a leap into truly two-dimensional materials engineering,” Pragathi Darapaneni, a materials scientist who helped develop graphene-enhanced silicon anodes for next-generation lithium-ion batteries at Martinrea International, told Built In. “It holds the key to innovations in faster electronics, more efficient energy systems and stronger, lighter materials for the future.”

Indeed, graphene carries enormous promise.The biggest hurdle now is figuring out how to manufacture it at scale — without losing all the remarkable properties that make it so promising.

What Is Graphene?

Graphene is a material that consists of a single layer of carbon atoms arranged in a hexagonal, honeycomb structure. Think of it as the basic building block of graphite (the same material found in pencil lead) only flattened to its most fundamental flake-form.

At just one atom thick, graphene is known for being the thinnest known material in the world, yet it is up to 200 times stronger than steel. It can also be modified to exhibit high electrical and thermal conductivity, as well as resistance, transparency and antimicrobial properties. It can even generate electricity when exposed to sunlight.

Because it is so versatile, graphene is being integrated into a wide range of technologies, including electronics, solar panels, medical devices and even sports equipment. Plus, its exceptional electron mobility at room temperature makes it a solid alternative to silicon in semiconductors, promising faster and more energy efficient performance.

Key Properties of Graphene

Graphene is unlike any other material known today.

What makes graphene so special is its natural ability to form super-strong “single atomic layers” of carbon that, at the same time, are easy to separate, according to William Lackowski, former chief scientist at the Center for Nano and Molecular Science and Technology at the University of Texas at Austin. These “ready-made and uniform” layers stick together only loosely, he told Built In, but each individual layer is very strong.

That’s a major advantage compared to other electronic materials, which have to be carefully grown in a lab or etched down to achieve that level of thinness and uniformity. “With graphene, you get a flat, atomically thin material right from the start,” Lackowski said, “which is an ideal canvas for making nanoscale devices.”

Some of graphene’s other main selling points include its:

- Ultra-Thinness: Just one atom thick, graphene is essentially two-dimensional.

- Exception Strength: Graphene is around 200 times stronger than steel by weight, with a psi of 150,000,000.

- High Conductivity: Graphene can move electrons 10 times faster than silicon, while using less energy and giving off less heat. It also conducts electricity and heat better than copper, making it ideal for next-gen electronics and thermal management.

- Flexibility: Graphene can bend and stretch without breaking, which makes it well-suited for wearables, flexible displays and soft robotics. In tensile tests, graphene has been shown to stretch up to a quarter of its original length without fracturing.

- Transparency: Despite being visible to the naked eye, freestanding graphene still allows about 97 percent of light to pass through a single flake — useful for solar panels, touchscreens and optical devices. (This gets more complicated when layered).

- High Surface Area: Just one gram of graphene can unfold to cover over 2,600 square meters — enough to span several football fields. This can be used to boost performance in batteries, sensors and industrial coatings.

- Chemical Stability: Graphene oxide can hold its structure up to about 300°C in air, and even higher (around 600°C) when heated in an inert atmosphere. Because of this resilience, it’s perfect for tough jobs like corrosion-resistant coatings, sensitive chemical sensors and fuel cell membranes that need to withstand harsh conditions.

How Is Graphene Being Used?

From epoxies used in aerospace and medical devices to advanced materials in high-end sporting equipment, graphene is being put to use in a wide variety of applications.

Electronics and Computing

Although most projects are still in the experimental stage, graphene is being used to develop high-speed transistors and photodetectors, as well as ultra-flexible display components. In 2010, IBM developed a graphene transistor that operates at 100 gigahertz — more than twice the speed of comparable silicon chips. The Cambridge Graphene Centre also developed the world’s first bendable display and graphene-based photodetectors that can fast-track optical communications for use in satellites, soft robotics and wearables.

Energy Storage

Energy storage — specifically battery technology — is one of the biggest bottlenecks holding back innovation across the entire electronics industry. To power next-generation devices, we need batteries that are light-weight, fast-charging and capable of storing large amounts of energy. Researchers think graphene may be the solution here, and are experimenting with graphene-based lithium-ion batteries, using it as an anode material to boost performance. Today, there are reportedly more than 300 companies developing graphene-based batteries and supercapacitors.

Wearables

Graphene’s flexible, lightweight and conductive qualities make it an ideal material choice for wearables. It can be woven into fabrics or embedded into sensors to monitor movement and health — and all without adding bulk or sacrificing comfort. For example, running shoe brand Inov-8 launched a first-of-its-kind series of trail running shoes with graphene-enhanced rubber soles, offering improved durability and grip. Graphene-based sensors are also being incorporated into smartwatches and fitness trackers, delivering more accurate data while ensuring these devices remain thin and comfortable to wear.

Medical and Biotech

Thanks to its exceptional conductivity, flexibility and relative safety, graphene is emerging as a leading material for medical and biotech applications — particularly sensors and drug delivery systems. For example, researchers have developed graphene-based electronic skin that can detect subtle changes in pressure and temperature, as well as non-invasive e-tattoos that measure blood pressure with clinical-grade accuracy.

Composites and Coatings

Adding graphene to other materials can boost strength and durability without adding extra weight. In aerospace, this means lighter aircraft wings and, as a result, greater fuel efficiency. In sports, gear like tennis rackets and skis can be more resilient. Graphene oxide-based coatings also protect metals like steel by blocking moisture and oxygen, improving their resistance to corrosion, scratches and even ice buildup.

Water Filtration

Graphene’s unique atomic structure allows water molecules to pass through while blocking almost all other liquids and gases, making it an ideal material for ultrafiltration — where tiny pores in a membrane are used to separate very small particles (viruses, proteins, etc.) from liquids. A major breakthrough on this front came from researchers at Columbia University, who developed monolayer graphene filters with pores as small as 5 nanometers — far smaller than those in conventional membranes. Because graphene is only one atom thick, these filters require less pressure to operate, making the filtration process more energy efficient. At the same time, graphene’s strength and flexibility make it less prone to cracking than current materials used.

Challenges of Graphene

Although graphene offers exceptional strength, high conductivity and various other benefits, it also faces some pretty major challenges that are holding it back from more widespread industrial use.

Hard to Scale

Producing high-quality, defect-free graphene at scale remains a major challenge, as most current techniques are either too expensive, too slow or too difficult to commercialize. Common methods like chemical vapor deposition can yield excellent results, but require specialized equipment and high temperatures, making it impractical for mass production. Another approach, liquid-phase exfoliation, is easier to scale, but often produces lower-quality, flawed graphene.

Inconsistent Material Quality

Graphene’s properties — such as its conductivity and strength — can vary significantly depending on how it’s made, what substrate it’s grown on and how it’s handled during processing. Even interacting with the air can alter its quality. This inconsistency makes it hard for high-precision industries like aerospace and electronics to rely on it for steady, reliable performance.

Lack of a Natural Bandgap

Unlike silicon, graphene does not naturally have a bandgap, meaning it can't easily switch off electrical current — a critical feature for digital transistors and computing. This limitation makes it difficult to replace silicon in traditional electronics, despite graphene’s other advantages.

Integration with Existing Technologies

Graphene often doesn’t fit seamlessly into today’s manufacturing ecosystems, which were built around conventional materials like silicon or copper. Incorporating it usually requires changes to equipment, processes or materials, adding extra costs and technical challenges that can deter commercial adoption.

“The big challenge right now is interfacing or connecting the graphene to other materials in the device with high reliability in a scalable manner,” Lackowski explained. “Getting inputs and outputs to ‘talk’ to it in a device is tricky, and patterning both the graphene and the interconnects at scale for complex electronics is a current hurdle.”

Potentially Toxic

Graphene’s interactions with living systems are still being studied, but early research suggests it can damage cell membranes or generate oxidative stress under certain conditions. That said, these risks appear low when it’s properly handled or embedded in products, as graphene is fundamentally the same form of carbon found in everyday graphite.

“To me, it’s a similar safety risk as shavings from sharpening a pencil,” Lackowski said.

Because graphene is so lightweight, it can easily become airborne during handling, so following standard lab safety protocols is recommended. While it’s not thought to be especially dangerous, caution is still advised since it’s a relatively new material and its long-term effects are not fully known yet.

Frequently Asked Questions

What is graphene mainly used for?

Graphene is used to improve batteries, strengthen lightweight materials in cars and planes, and is built into medical devices, water filters, electronics, solar panels, and sensors.

Is graphene dangerous to humans?

Graphene is generally safe, but when it’s broken down into tiny particles — like dust — it might be risky to breathe in. Researchers are still figuring out exactly how it affects the human body over time.

How strong is graphene?

Graphene is about 200 times stronger than steel and can withstand pressures up to 150,000,000 psi, making it one of the strongest known materials.

What is the biggest problem with graphene?

The biggest problem with graphene is producing it at scale in a cost-effective and consistent way. While it’s relatively easy to make tiny flakes of graphene in a lab, manufacturing large, defect-free sheets of it for industrial use is still difficult and expensive.

Where is graphene found?

Graphene itself isn’t found naturally in a free-standing form — it is extracted from graphite, which is a mineral that’s mined in various regions around the world, including China, Mozambique, Brazil, Madagascar and India.