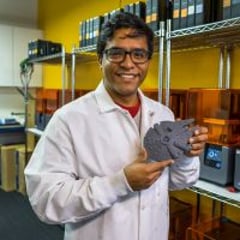

To reinvent an industry, you have to build the best team. Join Formlabs if you want to bring groundbreaking professional 3D printers to the desktop of every designer, engineer, researcher, and artist in the world.

Our passion is designing and building powerful 3D printing tools. Our manufacturing team is responsible for research and development of the manufacturing processes for all of Formlabs products. They work cross functionally with mechanical design, electrical, and materials teams.

If you’re excited to own an independent internship project within the manufacturing team, we want you as a Manufacturing Engineering Intern.

Internship Term: Winter/Spring (Target internship dates: January 13 to April 25, 2025)

Commitment: Full-time

Location: Onsite in Somerville, MA

The Job:

- As the principal investigator, conduct a research project on how manufacturing and/or calibration variations in a given printer subsystem affect Factory Test Print (FTP) performance and develop a proposal to improve the first-pass yield.

- Support the continuous improvement of test and calibration fixtures (e.g. tensioner, accelerometer, etc.), including fixture redesign, qualification, inventory / asset management, and preventive maintenance plans.

- Co-develop methods, processes, procedures, and work instructions to support building our next generation products.

You:

- Have working proficiency with CAD (e.g. Fusion, Solidworks, etc.) and 2D drawing creation

- Hands-on, self-motivated, and love to work on hardware

- Skilled at debugging, testing, and identifying the root causes of problems

- Organized, meticulous, and detail-oriented

- Independent, self-starter with strong communication skills

- Experience with statistical analysis and data visualization tools (SQL, Tableau, JMP, Minitab, etc)

- Experience with Python

Nice to Have:

- Have a desire to understand system level interactions of complex electro-mechanical products.

- Understanding of GD&T principles to define and evaluate part quality

Internships at Formlabs give students the opportunity to create, build, solve, and discover in every area of our business. Come build your career and build the future of 3D printing. Internship perks include social events, networking opportunities, access to our fully-stocked kitchens and onsite lunches, and unlimited 3D printing!

We are an equal opportunity employer and value diversity at our company. We do not discriminate on the basis of race, religion, color, national origin, gender, sexual orientation, age, marital status, veteran status, or disability status.

Even if you don't check every box, but see yourself contributing, please apply. Help us build an inclusive community that will change the face of 3D printing.

What We Do

We’re a passionate team of engineers, designers, and problem-solvers. Started out of MIT in 2011, Formlabs now employs over 700 people across offices in Germany, Japan, China and Somerville, Massachusetts. We're committed to bringing powerful and accessible fabrication tools into the creative hands of professionals around the world.

Why Work With Us

We’ve built a team 700+ strong across the world, and still counting. We look for people with an insatiable curiosity, a willingness to question the status quo, and a high capacity to get things done.

Gallery

Formlabs Offices

Hybrid Workspace

Employees engage in a combination of remote and on-site work.

Building the 3D tools of the future is not an easy task. To reach this ambitious goal, we need to react fast, iterate, and make changes on the fly. Our teams observe a flexible hybrid, where we all aim to be in office 3 days/week when possible.