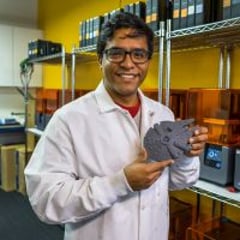

To reinvent an industry, you have to build the best team. Join Formlabs if you want to bring groundbreaking professional 3D printers to the desktop of every designer, engineer, researcher, and artist in the world.

Our printers require tightly integrated mechanical, electrical, optical and software systems to produce excellent parts every single print. Ensuring printer success requires deep technical knowledge of mechatronics as well as an ever-evolving understanding of how the product behaves in the field.

This role involves driving all stages of the product development cycle from early R+D to continuing engineering for shipped products. You’ll collaborate closely with design teams to overcome cross-disciplinary problems and ensure that we ship quality products. If you’re eager to collaborate with other talented engineers to support the full range of Formlabs products, we want you as a 3d Printing Systems Engineer.

The Job:

- Design and deliver key subsystem or subsystem components, including but not limited to laser, optics, high powered LEDs, LCDs, thermal systems, air handling system, tuning and calibration routines, sensing and/or motion control systems

- Analyze and debug hardware to the component level

- Conceptualize, select, and present technical solutions for a complex and highly integrated electro-mechanical system

- Support test and troubleshooting of systems, modules and sub-assemblies, working directly with program engineering personnel as required

- Generate and implement improvements in product and test design and methodologies to reduce cost, increase yield, and improve throughput

- Interfacing with multiple engineering disciplines (hardware, software, and specialty engineering) and equipment suppliers

- Supporting requirements definition and developing requirement specifications

You:

- Experience with the design, build, integration and/or test of complex electro-mechanical systems.

- Strong root cause analysis skills

- Able to research and apply engineering principles and theories to solve complex problems

- Motivated self-starter with skills and ability to effectively work in a team environment

- Ability to read and interpret electrical, optical, and mechanical technical drawings

Our Perks & Benefits:

- Robust equity program to build future wealth through RSUs

- Comprehensive healthcare coverage (Medical, Dental, Vision)

- Low cost fund options in our 401K and access to advisors

- Generous paid Parental Leave (up to 16 weeks)

- Tenure-based paid Sabbatical Leave (up to 6 weeks)

- Flexible Out of Office Plan – Take time when you need it

- Ample on-site parking & pre-tax commuter benefits

- Healthy on-site lunches, snacks, beverages, & treats

- Regular sponsored professional development opportunities

- Many opt-in culture events across our diverse community

- And of course… unlimited 3D prints

We are an equal opportunity employer and value diversity at our company. We do not discriminate on the basis of race, religion, color, national origin, gender, sexual orientation, age, marital status, veteran status, or disability status.

Even if you don't check every box, but see yourself contributing, please apply. Help us build an inclusive community that will change the face of 3D printing.

Top Skills

What We Do

We’re a passionate team of engineers, designers, and problem-solvers. Started out of MIT in 2011, Formlabs now employs over 700 people across offices in Germany, Japan, China and Somerville, Massachusetts. We're committed to bringing powerful and accessible fabrication tools into the creative hands of professionals around the world.

Why Work With Us

We’ve built a team 700+ strong across the world, and still counting. We look for people with an insatiable curiosity, a willingness to question the status quo, and a high capacity to get things done.

Gallery

Formlabs Offices

Hybrid Workspace

Employees engage in a combination of remote and on-site work.

Building the 3D tools of the future is not an easy task. To reach this ambitious goal, we need to react fast, iterate, and make changes on the fly. Our teams observe a flexible hybrid, where we all aim to be in office 3 days/week when possible.