Description

Onsite: This role is categorized as onsite. This means the successful candidate is expected to report to Lansing Delta on a full-time basis.

This job may be eligible for relocation benefits.

Sponsorship: GM DOES NOT PROVIDE IMMIGRATION-RELATED SPONSORSHIP FOR THIS ROLE. DO NOT APPLY FOR THIS ROLE IF YOU WILL NEED GM IMMIGRATION SPONSORSHIP (e.g., H-1B, TN, STEM OPT, etc.) NOW OR IN THE FUTURE.

The Role

The Manufacturing Execution Engineer GA for Mfg Optimization will be responsible for executing GA manufacturing optimization projects across various assembly sites, which includes collaborating with cross functional teams across Manufacturing Engineering, Plant Production, Quality and Maintenance Teams to design, build and Commission state of the art Automation Projects in our Vehicle Assembly Plants. This is a unique opportunity to influence the way we, as General Motors, operate within General Assembly in our assembly plants and lead the way to GM achieving a factory of the future. You will be responsible, while working with GA ME, to maximize efficiency while reducing MCPU. Requirements would include effective utilization of personnel, material, machines and facilities necessary for a flawless execution.

Key Deliverables will be to coordinate projects, plan, develop and execute GA Optimization projects from ideation to installation to create the most efficient, leanest processes for the entire GM Enterprise. This individual will work with all levels of cross functional teams. Work is performed in a centralized manufacturing engineering facility as well as assembly plant with an elevated level of independent judgment.

What You Will Do (Responsibilities)

- Define all areas of change, which include product and manufacturing requirements (tooling, automation, workstation setup, facility and etc.)

- Efficient material flow understandings for future material movement

- Develop interfaces, and work with cross functional teams to develop / define common tooling and process across whole department and other groups

- Providing technical direction to and oversight of outside vendor sources and product/plant teams

- Design, construction, integration, plant installation, successful launch and continuous improvement of equipment and tools required in plants for the production of high quality vehicles.

- Lead coordination of automation projects including all Plant integration and pull ahead activities with Continuous Improvement leads, Plant ME/IE Teams.

- High level of analytical ability & problem solving where problems are unusual and difficult.

- High level of problem solving and issue resolution aptitude

- Technical capability with knowledge of automated processes

- Complete project plan reviews with the local production management teams for future implementations. Understand local contractual considerations for all projects.

- Provide Technical support and assistance to manufacturing and maintenance team members, production supervisors and production associates.

- Ensure meeting financial and budget requirements set for projects.

- Able to quickly understand a Layout and propose ideas to Automate General Assembly tooling / solutions.

- Have complete understanding of Bill of Processes (BOP) / Bill of Equipment (BOE).

- Manage Timing, Resources, Budget, Lessons Learned, Performance Scorecard, Meeting Minutes, One Pager project weekly report for every project that this individual will lead.

- Support Performance Integration of vehicle, especially driving design solutions to integration issues.

- Responsible for Engineering Deliverable status at Program Execution Team and Program Quality Readiness Reviews

- Engineering launch leadership including on sight leadership at Assembly Plant Launches.

- Run Vehicle & Progress Integration Meetings

- Engineering interface to Plant Operations including build support and issue resolution, Bill Of Materials and final vehicle completeness.

Additional Description

Your Skills & Abilities (Required Qualifications)

- Bachelors Degree in Mechanical Engineering or equivalent experience

- 4+ years of experience in manufacturing engineering experience

- 3+ years of experience in manufacturing launch experience

- Ability to work independently, make decisions and drive escalations as required.

- High level of collaboration and cross-functional skills to work effectively with others.

- Strong data management, analysis, presentation, and problem solving skills where they are unusual and difficult.

- Be creative to provide ideas and action oriented to execute them.

- Highly Proficient with Team Center, AutoDesk, MS-Office tools (Excel, Visio, Project and Powerpoint).

- Previous experience Leading individual complex projects, with the ability to coordinate resources, report status, and track timelines.

- Deep technical knowledge and ability in process engineering disciplines

- Deep knowledge and ability to implement GMS principles

- Thorough knowledge of Manufacturing Processes, Tooling and Equipment. Also, the Global Launch Process and Vehicle Development Process.

- Demonstrated ability to manage multiple and significantly complex projects and assignments with highest level of autonomy and accountability for results

- Proven ability in project management skills and ability to teach others

- Ability to influence people across the organization. Act as a change agent.

- Being available to travel up to 50% within US as required in each phase of the project.

What Will Give You a Competitive Edge (Preferred Qualifications)

- Previous experience with Scoping, Design, Integration, Commissioning various levels of Automation projects.

- Experience working in a unionized manufacturing operation.

- Thorough knowledge of Manufacturing Processes, Tooling and Equipment, and how it relates to the Global Launch Process and Vehicle Development Process.

- Knowledge and familiarity with general assembly tooling automation and concepts.

Onsite: This role is categorized as onsite. This means the successful candidate is expected to report to Lansing Delta on a full-time basis.

This job may be eligible for relocation benefits.

Sponsorship: GM DOES NOT PROVIDE IMMIGRATION-RELATED SPONSORSHIP FOR THIS ROLE. DO NOT APPLY FOR THIS ROLE IF YOU WILL NEED GM IMMIGRATION SPONSORSHIP (e.g., H-1B, TN, STEM OPT, etc.) NOW OR IN THE FUTURE.

About GM

Our vision is a world with Zero Crashes, Zero Emissions and Zero Congestion and we embrace the responsibility to lead the change that will make our world better, safer and more equitable for all.

Why Join Us

We believe we all must make a choice every day - individually and collectively - to drive meaningful change through our words, our deeds and our culture. Every day, we want every employee, no matter their background, ethnicity, preferences, or location, to feel they belong to one General Motors team.

Total Rewards | Benefits Overview

From day one, we're looking out for your well-being-at work and at home-so you can focus on realizing your ambitions. Learn how GM supports a rewarding career that rewards you personally by visiting Total Rewards resources.

Non-Discrimination and Equal Employment Opportunities (U.S.)

General Motors is committed to being a workplace that is not only free of unlawful discrimination, but one that genuinely fosters inclusion and belonging. We strongly believe that providing an inclusive workplace creates an environment in which our employees can thrive and develop better products for our customers.

All employment decisions are made on a non-discriminatory basis without regard to sex, race, color, national origin, citizenship status, religion, age, disability, pregnancy or maternity status, sexual orientation, gender identity, status as a veteran or protected veteran, or any other similarly protected status in accordance with federal, state and local laws.

We encourage interested candidates to review the key responsibilities and qualifications for each role and apply for any positions that match their skills and capabilities. Applicants in the recruitment process may be required, where applicable, to successfully complete a role-related assessment(s) and/or a pre-employment screening prior to beginning employment. To learn more, visit How we Hire.

Accommodations (U.S. and Canada)

General Motors offers opportunities to all job seekers including individuals with disabilities. If you need a reasonable accommodation to assist with your job search or application for employment, email us [email protected] or call us at 800-865-7580. In your email, please include a description of the specific accommodation you are requesting as well as the job title and requisition number of the position for which you are applying.

What We Do

At General Motors, our vision is to create a world with Zero Crashes, Zero Emissions, and Zero Congestion. We wholeheartedly embrace the responsibility to lead the change that will make our world better, safer, and more equitable for all.

Our industry and company are undergoing a once-in-a-lifetime technological transformation, which is reshaping our approach to technology and innovation. We are expanding our horizons through new technology platforms and driving innovations that deliver exceptional value to our customers.

Why Work With Us

At General Motors, our purpose is to pioneer the innovations that move and connect people to what matters. We’re driving the world forward, together. We’re building vehicle software alongside its hardware, hands-free driving that will lead to autonomy, and EVs that charge your home for an all-electric future.

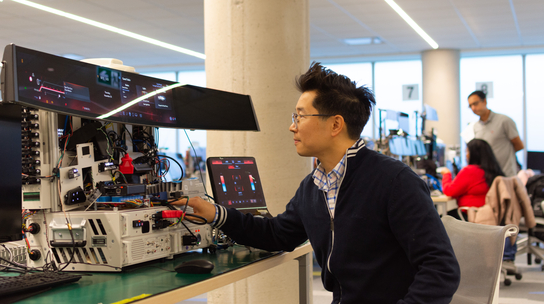

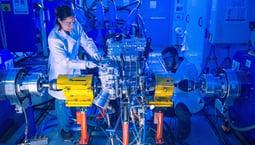

Gallery

General Motors Offices

Hybrid Workspace

Employees engage in a combination of remote and on-site work.

Roles that are categorized as Hybrid mean that the successful candidate is expected to report onsite to the designated facility at least three times per week or other frequency as dictated by the business.