Description

Sponsorship: GM DOES NOT PROVIDE IMMIGRATION-RELATED SPONSORSHIP FOR THIS ROLE. DO NOT APPLY FOR THIS ROLE IF YOU WILL NEED GM IMMIGRATION SPONSORSHIP (e.g., H-1B, TN, STEM OPT, etc.) NOW OR IN THE FUTURE.

On-site: This role is categorized as onsite. This means the successful candidate is expected to report to Factory Zero on a full-time basis.

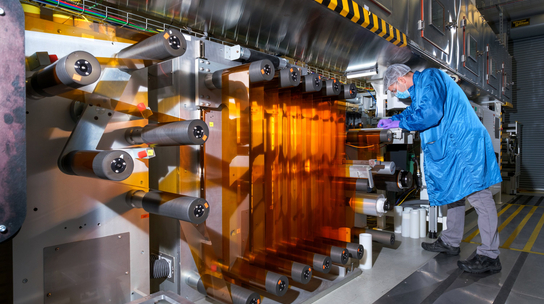

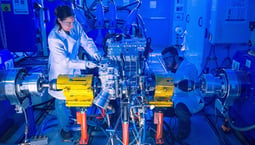

Factory ZERO is our first, all-electric automotive assembly plant and the blueprint of General Motors' electric future! We have a corporate vision of "Zero crashes, Zero emissions, Zero congestion." Our most novel products like the Hummer EV and our very first autonomous vehicle, Cruise Origin will be assembled right in this facility. This requires us to employ the most upbeat, capable, and innovative talent to ensure we meet the challenges of developing the new manufacturing processes required to assemble these outstanding products! We offer a multifaceted and inclusive work environment that questions the status-quo daily to strengthen our reputation. Selected candidates will have the opportunity to learn new skills and actively play an integral role in the development of new processes here at Factory Zero.

The Role:

The Lead Controls Engineer be able to work autonomously with occasional guidance from supervision and ME Controls Lead Engineer. Skilled in PLC, HMI, Robot, Weld, Torque and Test control systems; Manufacturing Plant Floor Systems like Production Monitoring, Routing & Tracking and Error Proofing, Torque and Weld Monitoring; Equipment, tooling, facilities, and alternatives. Knowledgeable in sequence and flow of operations for the effective utilization of personnel, material, machines, and facilities necessary for supporting production. Work is performed in an assembly plant manufacturing engineering activity where creativity and initiative are exercised as well as independent judgement. You will be responsible for leading controls engineering activities for the smooth functioning of all manufacturing equipment and manufacturing support systems in the General Assembly area at the Factory Zero plant.

What You'll Do:

In this position you will provide leadership to controls engineers, in all shifts, directly supporting the General Assembly department and indirectly reporting to ME, in support of meeting or exceeding General Assembly department's SPQRCE metrics; compliance to Safety regulations; compliance to ME Cyber Security requirements and ME Cornerstone requirements. Your responsibilities will be of a technical nature with decisions made within the limits of general practices, policies, and standards. Your work will involve complex manufacturing problems including the need to root cause and follow up to resolve safety, quality, and throughput issues.

- Support Production TIP - Throughput Improvement activities, material, machines, and facilities necessary for supporting production. Work is performed in an assembly plant manufacturing engineering activity where creativity and initiative are exercised as well as independent judgment.

- Responsible for identifying and upskilling of controls engineers' and skilled trades (electricians) technical skills.

- Training others in: Predictive Equipment - Temperature/Thermal Cameras, Vibration Sensing Equipment, Laser Alignment Equipment.

- Collection and storage of documentation (lock-out maps, electrical drawings) of manufacturing equipment for compliance and quick recovery.

Additional Description

Your Skills & Abilities (Required Qualifications):

- Bachelor's degree or equivalent experience (Electrical Engineering degree preferred)

- 3+ years of experience in PLC Programming.

- 3+ years of experience in Manufacturing plant floor systems - Manufacturing Plant Floor Systems like Production Monitoring, Routing & Tracking and Error Proofing, Torque and Weld Monitoring.

- Proficient knowledge in Rockwell PLCs, HMIs, Fanuc Robots.

- Experience with Diagnosis process equipment failures.

- Working knowledge of process equipment operations, sequence, error proofing and diagnostics capabilities.

- Knowledge of drives / motion control.

- Knowledge of Fastening tools and controllers mainly Atlas Copco.

- Knowledge of barcode scanning and printing.

- Knowledge of vision systems.

What Can Give You a Competitive Edge (Preferred Qualifications):

- Previous vehicle diagnostic experience

- Previous General Assembly group leader experience

- Knowledge of Team Center.

- Knowledge of automated welding and adhesive/sealing dispense.

- Knowledge of Maximo.

- Knowledge of Facility Electrical Systems.

This job may be eligible for relocation benefits.

About GM

Our vision is a world with Zero Crashes, Zero Emissions and Zero Congestion and we embrace the responsibility to lead the change that will make our world better, safer and more equitable for all.

Why Join Us

We aspire to be the most inclusive company in the world. We believe we all must make a choice every day - individually and collectively - to drive meaningful change through our words, our deeds and our culture. Every day, we want every employee, no matter their background, ethnicity, preferences, or location, to feel they belong to one General Motors team.

Total Rewards | Benefits Overview

From day one, we're looking out for your well-being-at work and at home-so you can focus on realizing your ambitions. Learn how GM supports a rewarding career that rewards you personally by visiting Total Rewards resources.

Diversity Information

General Motors is committed to being a workplace that is not only free of unlawful discrimination, but one that genuinely fosters inclusion and belonging. We strongly believe that workforce diversity creates an environment in which our employees can thrive and develop better products for our customers. We encourage interested candidates to review the key responsibilities and qualifications for each role and apply for any positions that match their skills and capabilities. Applicants in the recruitment process may be required, where applicable, to successfully complete a role-related assessment(s) and/or a pre-employment screening prior to beginning employment. To learn more, visit How we Hire

Equal Employment Opportunity Statement (U.S.)

General Motors is proud to be an equal opportunity employer. All qualified applicants will receive consideration for employment without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, disability, or status as a protected veteran.

Accommodations (U.S. and Canada)

General Motors offers opportunities to all job seekers including individuals with disabilities. If you need a reasonable accommodation to assist with your job search or application for employment, email us [email protected] or call us at 800-865-7580. In your email, please include a description of the specific accommodation you are requesting as well as the job title and requisition number of the position for which you are applying.

Top Skills

What We Do

At General Motors, our vision is to create a world with Zero Crashes, Zero Emissions, and Zero Congestion. We wholeheartedly embrace the responsibility to lead the change that will make our world better, safer, and more equitable for all.

Our industry and company are undergoing a once-in-a-lifetime technological transformation, which is reshaping our approach to technology and innovation. We are expanding our horizons through new technology platforms and driving innovations that deliver exceptional value to our customers.

Why Work With Us

We are determined to lead change for the world through technology, ingenuity and harnessing the creativity of our diverse team. Our “Work Appropriately” philosophy enables our employees have the flexibility to work where they can have the greatest impact to achieve their goals and for their individual success, depending on the nature of their work.

Gallery

General Motors Offices

Hybrid Workspace

Employees engage in a combination of remote and on-site work.