The role:

The Industrial Engineer is an integral part to daily and future engine assembly and machining operations. The Industrial Engineer will lead initiatives to eliminate the waste of time, money, materials, person-hours, machine time, energy, and other resources that do not generate value at Spring Hill GPS.

Work is of a technical nature and focused on making complex manufacturing processes more efficient, which involves understanding the systematic cross functionality of several departments, including engine machining, engine assembly, quality, maintenance, and supply chain. Significant use of independent judgment is required, as well as the ability to think critically and creatively to solve problems and drive projects forward.

The Industrial Engineer will lead and support complex production projects, including automation initiatives, and drive the proactive resolution of Throughput Improvement Process (TIP) initiatives that involve collaboration between several in-plant departments, Headquarters engineering organizations, UAW team members, and third-party suppliers and contractors. Exceptional communication and relationship building skills are essential for success in this role.

What you'll do:

- Design work operations that meet safety, quality, takt, and efficiency requirements

- Lead initiatives to increase throughput across engine assembly and machining lines

- Utilize the Theory of Constraints and analyze faults, bottlenecks, maximum throughput, and downtime to drive continuous improvement

- Analyze machine modes of failure and repair processes to drive improvements, promote uptime, and prioritize preventative maintenance

- Manage, plan, and execute large-scale production projects that involve the introduction of robotic cells, cobots, and other automated assembly line equipment

- Evaluate project feasibility and capability by performing cycle time analysis and providing data to feed simulation models

- Support tool design, lift assist design, and material packaging design

- Design flow racks and other forms of lineside material presentation to meet ergonomic requirements and to minimize non-value-added movement

- Develop automated and manual station workflows and layouts to meet takt requirements

- Collaborate with multiple departments to determine space allocation needs and make subsequent layout revisions using AutoCAD

- Revise assembly line flow and build sequence to support automation and rebalance projects according to the Engine Assembly Document (EAD)

- Participate in safety buyoff processes, including g-Risks and g-Comply, for new equipment and automation

- Travel to equipment suppliers as needed to support the runoff process

- Coach production teams and operations leadership on lean manufacturing principles through the Global Manufacturing System (GMS) framework

- Develop and drive Continuous Improvement Processes (CIPs) by evaluating current job functions for rebalance opportunities or opportunities to drive additional production efficiency and/or reductions in labor cost

- Maintain accurate time studies using motion analysis and standard time data

- Maintain clear and accurate work instructions to ensure build quality and team member safety

- Provide technical support and assistance to manufacturing and maintenance team members, production supervisors, and production team members

- Develop, maintain, and analyze Manufacturing Master Schedules in sufficient detail to monitor progress, assess program status, and identify performance issues in a timely manner

- Lead and support Operational Excellence projects

- Monitor adherence to recommended Safety procedures and ergonomics guidelines

Your Skills and Abilities (Required Qualifications):

- Bachelor's degree in engineering, or a related degree, or 4+ years of equivalent experience in lieu of a bachelor's degree

- 2+ years of work or educational experience in data analytics

- 2+ years of work or educational experience in automation, robotics, or general programming

- 1+ years of work or educational experience in manufacturing and/or manufacturing systems

- 1+ years of work or educational experience in human factors (time studies, ergonomics, human-computer-interaction, etc.)

- High level of interpersonal, communication, and project management skills

- Demonstrated ability to analyze and solve complex problems

- Experience leading large and difficult projects with a high level of autonomy

- Experience with throughput analysis

- Ability to work off-shift, weekends, or overtime

What will give you a competitive edge (Preferred Qualifications):

- 2+ years of manufacturing experience

- Experience optimizing machining operations

- Proficiency in AutoCAD or other computer-aided drafting and layout tools

- Experience implementing robotic cells, material automation, cobots, or other types of automation

- Experience working in a unionized manufacturing environment

- Lean Six Sigma Green Belt certification

About GM

Our vision is a world with Zero Crashes, Zero Emissions and Zero Congestion and we embrace the responsibility to lead the change that will make our world better, safer and more equitable for all.

Why Join Us

We believe we all must make a choice every day - individually and collectively - to drive meaningful change through our words, our deeds and our culture. Every day, we want every employee to feel they belong to one General Motors team.

Total Rewards | Benefits Overview

From day one, we're looking out for your well-being-at work and at home-so you can focus on realizing your ambitions. Learn how GM supports a rewarding career that rewards you personally by visiting Total Rewards resources.

Non-Discrimination and Equal Employment Opportunities (U.S.)

General Motors is committed to being a workplace that is not only free of unlawful discrimination, but one that genuinely fosters inclusion and belonging. We strongly believe that providing an inclusive workplace creates an environment in which our employees can thrive and develop better products for our customers.

All employment decisions are made on a non-discriminatory basis without regard to sex, race, color, national origin, citizenship status, religion, age, disability, pregnancy or maternity status, sexual orientation, gender identity, status as a veteran or protected veteran, or any other similarly protected status in accordance with federal, state and local laws.

We encourage interested candidates to review the key responsibilities and qualifications for each role and apply for any positions that match their skills and capabilities. Applicants in the recruitment process may be required, where applicable, to successfully complete a role-related assessment(s) and/or a pre-employment screening prior to beginning employment. To learn more, visit How we Hire.

Accommodations

General Motors offers opportunities to all job seekers including individuals with disabilities. If you need a reasonable accommodation to assist with your job search or application for employment, email us [email protected] or call us at 800-865-7580. In your email, please include a description of the specific accommodation you are requesting as well as the job title and requisition number of the position for which you are applying.

Top Skills

What We Do

At General Motors, our vision is to create a world with Zero Crashes, Zero Emissions, and Zero Congestion. We wholeheartedly embrace the responsibility to lead the change that will make our world better, safer, and more equitable for all.

Our industry and company are undergoing a once-in-a-lifetime technological transformation, which is reshaping our approach to technology and innovation. We are expanding our horizons through new technology platforms and driving innovations that deliver exceptional value to our customers.

Why Work With Us

At General Motors, our purpose is to pioneer the innovations that move and connect people to what matters. We’re driving the world forward, together. We’re building vehicle software alongside its hardware, hands-free driving that will lead to autonomy, and EVs that charge your home for an all-electric future.

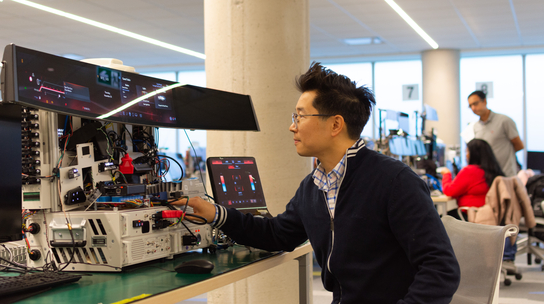

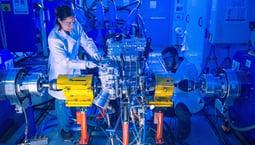

Gallery

General Motors Offices

Hybrid Workspace

Employees engage in a combination of remote and on-site work.

Roles that are categorized as Hybrid mean that the successful candidate is expected to report onsite to the designated facility at least three times per week or other frequency as dictated by the business.